AI in Warehouse Management

Logistic and supply chain pressures are continuously driving warehouses to operate faster, more accurately, and more cost-effectively. As e-commerce continues to grow and customers increasingly expect faster delivery, traditional warehouse management is facing challenges in adapting to the new levels of complexity and operational volume.

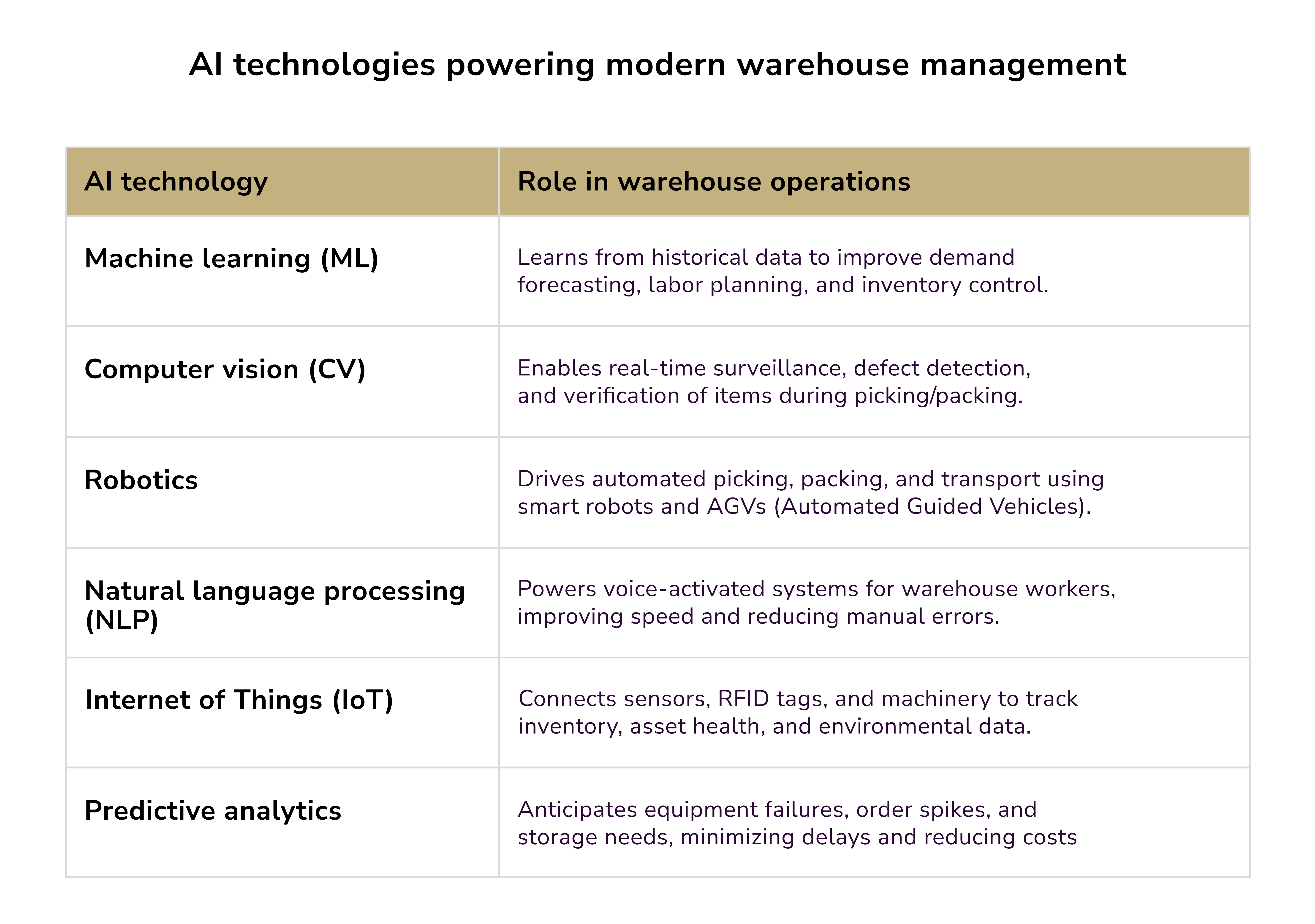

To fulfill these requirements, warehouse management systems (WMS) have turned to intelligent technologies, such as custom AI development, to increase visibility, accuracy, cost-efficiency, and speed of fulfillment operations. Autonomous drones, robotic arms, and human-machine collaboration are the new trends in the warehousing industry, and they are solidifying their positions.

We need to understand these innovations, how they fit in warehousing, and the value they bring.

Intelligent Warehouse Management

A conventional WMS is designed to control and direct the day-to-day warehouse activities such as receiving, put-away, picking, packing, and shipping. An AI-based WMS goes beyond that. It is powered by machine learning algorithms to process data, anticipate trends, and automate complex decisions.

Proper warehouse management involves space planning, inventory oversight, and ensuring timely order fulfillment. One of the main uses of AI in warehouse management is managing physical warehouse space and product placement. The strategic assignment of items to storage bin locations can significantly impact picking, packing, and shipping efficiency. AI-based tools process vast amounts of data to make these decisions with an accuracy that is not achievable manually.

An effective optimization strategy is classifying inventory into hot and cold categories:

- Hot storage refers to areas that hold high-demand, fast-moving goods. These items are stored in convenient locations close to the packing stations, for example, on low shelves, to reduce walking distance for the warehouse workers and the robotic unit.

- Cold storage is defined as stock that moves slowly. These items may be kept in harder-to-find places, and it will still not significantly affect the efficiency of operations.

AI-powered algorithms are instrumental in this classification process. Using historical sales data, seasonality, promotional schedules, and even external market trends, AI systems identify the best sellers. As demand patterns change, the AI dynamically reclassifies products as either hot or cold, actively refining the warehouse configuration. By using dynamic slotting, companies reduce pick times, lower labor costs, and speed up order fulfillment.

Intelligent Inventory Forecasting

Keeping inventory levels at a balance point has been one of the biggest challenges in the logistics industry. Having too much or too little stock can be equally costly for companies that store a variety of products across multiple distribution centers. Overstocking ties up working capital, increases storage requirements, and may require discounting or product obsolescence. Understocking, in contrast, leads to sales losses, reduced customer satisfaction, and downstream propagation through logistics.

Traditional forecasting methods relied on historical data and static rules that didn't account for external factors such as inclement weather, promotional events, or local trends. This inability to act quickly often led to mismatched inventory levels and reactive fulfillment strategies.

Applying AI to financial forecasting, as well as machine learning algorithms that consider historical sales data, seasonality, real-time weather information, and socio-economic trends, AI solutions can now forecast demand accurately. These models learn from data inputs and dynamically recalibrate, enabling warehouse planners to make forward-looking stock placement and replenishment decisions based on anticipated changes in market or customer demand.

A prime example is Walmart, which uses AI-powered forecasting systems that factor a variety of information — weather, local events, consumer behavior — when managing its inventory across the network, especially during seasonal peaks and promotional events. This forecasting enables the company to avoid overstocking and product outages even in fickle markets.

In a similar note, ORION, developed by UPS for route optimization, is another example of predictive analytics in logistics. ORION, by crunching 250 million address points to shave delivery miles and time, demonstrates a strategy that warehouse planners are now transferring to demand forecasting models.

Warehouse Layout and Routing Optimization

The physical design and flow of a modern warehouse directly impact throughput, labor efficiency, and operating costs. And yet, many warehouses still use static layouts and fixed picker routes that aren't based on demand. This creates inefficiencies such as order pickers crisscrossing the warehouse to fetch parts of a high-velocity order, congestion, pickers bunched up in busy aisles, and poor utilization of the warehouse's vertical space.

AI addresses this issue by generating adaptable, data-driven warehouse layouts and delivery paths in pairs. AI models are constantly adapting warehouse storage patterns and delivery sequences to best fit current orders by efficiently organizing pickers' routes.

With dynamic layout planning enabled by intelligent routing, AI enables warehouses to shrink in size without losing capacity or accessibility. In addition, because pickers travel less, injuries are reduced, contributing to sustainability and happier employees. These operational efficiencies are critical, particularly for companies that operate multi-site fulfillment networks and are bound by stringent service-level agreements (SLAs).

Robotic and Automated Systems in Warehouse Management

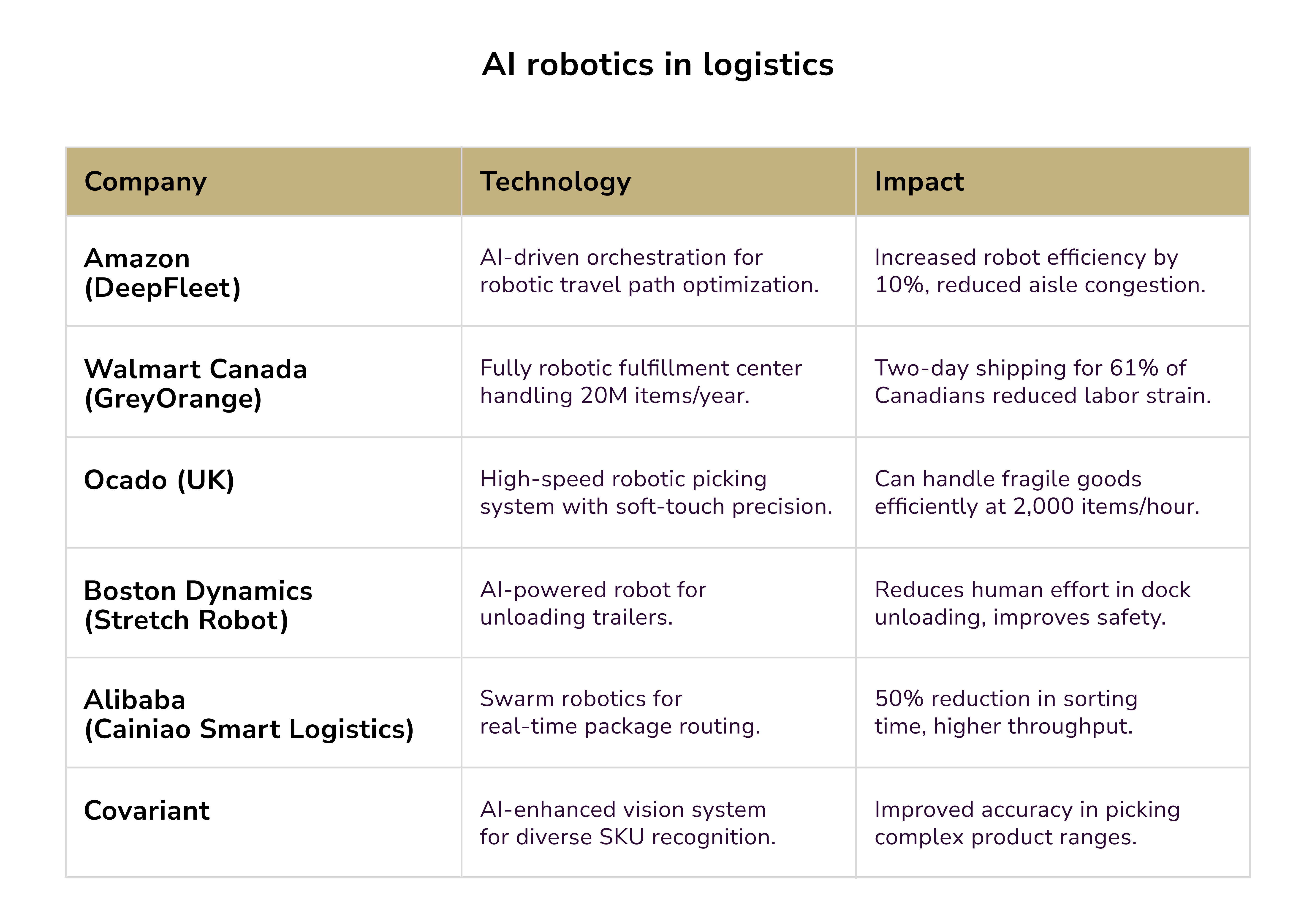

The management of warehouse operations has been significantly enhanced by the integration of robotic and automated systems, which can now perform the majority of repetitive, low-value tasks. The implementation of these technologies in smart warehouses facilitates improvements in operational efficiency, accuracy, and consistency at scale. Various types of warehouse automation systems exist, each designed to support specific applications and provide distinct advantages.

Autonomous Mobile Robots (AMRs)

AMRs are a unique type of self-driving robot. While traditional automated robots are constrained to predefined paths, AMRs can navigate environments autonomously. They use an array of tools, differentiating them from traditional robots, such as multispectral sensors, vision systems, and self-supervised deep learning. AMRs streamline the shipping of various items, including individual packages, pallets, and even shelving units, making them an invaluable asset to an organization.

Most AMRs focus on:

- Shipping items to workers stationed at certain locations in the warehouse.

- Refilling inventory based on automated demand predictions.

- Transporting returned items to inspection zones.

AMRs can customize their systems and be deployed almost immediately. Their deployment time is also relatively short, with many systems, particularly those offered under a robotics-as-a-service (RaaS) model, becoming operational within weeks to months. Custom-built AMRs may require a longer deployment period.

Automated Guided Vehicles (AGVs)

Automated guided vehicles, or AGVs, are automated vehicles programmed to follow fixed paths. They utilize various navigation technologies, such as sensors, magnetic tape, wires, or lasers, to guide their movement within a smart warehouse. Unlike AMRs, AGVs do not have a high level of autonomy; they are bound to their programmed paths.

Key use cases for AGVs include:

- Handling and transporting cargo (raw and finished) between different operational zones and storage locations.

- Moving and transferring pallets between receiving, storage, and shipping zones.

- Transferring goods from inbound receiving docks to outbound shipping docks.

AGVs present a cost-effective solution for a multitude of operational tasks within a warehouse. Due to their operational reliance on fixed paths, their operational stability, predictability, and reliability are quite high. The data and tracking infrastructure needed, however, are big contributors to the high initial costs.

Automated Storage and Retrieval Systems (AS/RS)

AS/RS are advanced automation systems that combine computer vision and high-density storage retrieval mechanisms (shuttles, robotic arms, or cranes) in order to store and retrieve products automatically. AS/RS systems are extremely valuable in warehouses with tall, skinny aisles, as they eliminate the need for manual forklift use.

Common use cases of AS/RS are:

- Compact storage of products in vertical racking systems.

- Automated retrieval of products during order fulfillment for high-velocity processes.

- Management of temperature-sensitive products in cold-warehouse environments.

AS/RS systems are well-suited for warehouses short on space and offer considerable long-term positive ROI, mainly due to savings in manual labor. However, they also require significant investment and time to implement. Additionally, AS/RS may lack the flexibility for organizations with quickly changing inventory profiles.

The Business Value of Investing in Robotics

For logistics companies, the integration of robotics into the warehousing processes provides benefits in productivity, cost savings, and risk mitigation.

- Increased efficiency and throughput. The automation of retrieving goods allows for greater efficiencies and fulfillment speeds:a picker using a G2P system can complete hundreds of orders an hour.

- Significant reduction in errors. In a computerized robotics system, the scan-and-pack systems reduce human error through computer vision, automated verification, and order cross-checking, resulting in near-perfect accuracy.

- Substantial cost savings. While there is an upfront investment, warehouse robotics leads to significant long-term cost savings. These savings come from several areas:

- 1) Labor costs decrease because robots perform repetitive tasks manually, which helps organizations control their workforce expenses during busy times and in limited labor markets.

- 2) Fewer errors mean lower costs associated with returns and redeliveries.

- 3) G2P and AS/RS systems can increase storage density by up to 80%, delaying or eliminating the need for costly warehouse expansion.

- Improved workplace safety. Robots take on the most physically strenuous tasks, such as carrying heavy loads over long distances. The system reduces workplace accidents, improving employee safety, increasing job satisfaction, and lowering workers' compensation expenses.

Computer Vision in Warehouse Quality Control

Computer vision is a subset of AI that allows computers to interpret and make sense of the visual world. In a warehouse environment, it is a system of cameras and sensors located at key points that send visual information to an AI platform.

A computer vision system doesn't just look at the code; it sees the entire package. It processes the image to detect shapes, sizes, text (using optical character recognition), tags, and even the physical state. It runs a visual check against a digital library of what the product should look like. For example, if a box is dented, a label is missing, or the wrong item has been sent, the system pinpoints the error right away.

Defect Detection

A great use case for computer vision is defect detection automation. Traditionally, quality control inspectors manually check goods as they arrive at the receiving dock or before they leave the shipping bay. This process is slow and prone to inconsistency.

Computer vision systems automate this by scanning items on high-speed conveyor belts. It uses AI models trained on thousands of images to distinguish "perfect" products from defective ones.

How does it work?

- Surface inspection: It finds scratches, dents, tears, or holes in packaging.

- Structural integrity: This can detect crushed corners or boxes with compromised structure.

- Label checking: It verifies that the labels are present, have readable text, and aren't wrinkled or ripped.

By identifying damaged goods at the receiving stage, warehouses avoid the liability for vendor mistakes. Meanwhile, by identifying damaged packages at the shipping stage, they eliminate adverse customer experiences.

Example: Amazon is a leader in this space. The company's centers integrate Amazon One with other vision tech to monitor items. Their Just Walk Out tech, used in retail and based on warehouse principles, implements computer vision to monitor which items are taken from shelves. Within their warehouses, computer vision identifies damaged inventory and verifies that the correct item is in the correct pod, which is being carried by their Kiva robots.

Order Accuracy and Fulfillment

The "pick and pack" process is where most warehouse errors occur. A picker might grab a medium shirt instead of a large one, or a blue phone case instead of a black one. Computer vision acts as an automated auditor at the packing station.

How does it work?

When a picker drops items into a shipping bin, an overhead camera snaps a photo of the contents. The system compares the image with the customer's order. It checks:

- Number of parts: Are there three pieces in the container as ordered?

- Item identity: Does the item match its visual profile?

- Packaging: Is the product packed with proper dunnage (bubble wrap, paper)?

If the system picks up an irregularity, such as a missing item or a product that does not match the SKU's visual profile, it either stops the line or notifies the packer to fix the issue before the box is sealed. This delivers almost 100% accuracy, which greatly diminishes the cost of return logistics.

Example: DHL has deployed Vision Picking using smart glasses. Basically, it uses Augmented Reality (AR) but is based on computer vision techniques. The glasses are equipped with cameras that read barcodes and recognize shelves to visually guide pickers to the right product. This hands-free picking method has increased picking productivity by up to 15% and reduced error rates.

Inventory Verification

Inventory precision is a core principle in warehouse management, and when it is done manually, it involves inefficient cycle counts, where workers shut down lanes to do a stock count.

Computer vision is changing this through business process automation and mobility:

- Drone-assisted counting: Some warehouses employ autonomous drones with computer vision capabilities to scan the warehouse from above. They do off-hours stock counts with computer vision scanning high shelves and boxes. This way, employees can verify that the stock visually matches the records.

- Shelf-mounted cameras: Other warehouses scan shelves with motion-mounted cameras on a forklift or robotic arm as they operate. They find empty boxes (stockouts), gaps (misplaced inventories), and other indicators of low stock. This gives managers a real-time view of inventory without the high costs of manual counting.

Example: IKEA has rolled out autonomous drones in a number of its distribution centers. Leveraging computer vision and 3D mapping, the drones perform the inventory take at night. This enables IKEA to maintain very accurate stock levels without impacting its day-to-day processes or requiring its employees to work at dangerous heights.

Enhancing Worker Safety with AI

Employees are the most important aspect of the business. Systems built on AI technology provide uninterrupted support to prevent negative events and ensure a positive environment. In the context of a warehouse, AI can prevent accidents by predicting the future using algorithms and analyzing multiple data sources, such as accident records, near misses, and data from varying maintenance controls for equipment.

The more data the AI can analyze, and the more accurately algorithms can identify patterns, the fewer negative events will occur. For instance, the system can predict that a certain area of the warehouse is likely to have accidents, such as forklifts colliding with pedestrians. AI will target that area with improvement suggestions, such as installing visible traffic signs, improving alternate traffic designs, or providing additional operator training.

Computer Vision for Real-Time Monitoring

Computer vision might be one of the most effective solutions for warehouse safety. Cameras with embedded AI software can observe the entire facility live and detect unsafe behaviors or situations on the spot.

Key applications include:

- PPE detection: The system can confirm that workers are wearing all required PPE, including hard hats, safety vests, and steel-toe boots. The platform can send an alert to the staff member and manager if a worker is detected entering a restricted area without appropriate attire.

- Collision prevention: Artificial intelligence can keep track of forklifts, AMRs, and pedestrians. The system can also anticipate potentially colliding trajectories, notify operators, and even intervene by decelerating or braking a vehicle to avoid an accident.

- Ergonomic assessment: Using computer vision, logistic firms can assess a worker's posture and movements during lifting and other physical work. The system can help detect dangerous movements that may cause musculoskeletal injuries in the future. It can provide feedback and training advice to eliminate or reduce the risks of the issue occurring.

Augmented Workforce Technologies

The use of AI in the warehouse is not limited to optimizing repetitive tasks that require heavy lifting; it can also help improve employees' skills and knowledge, enabling them to perform their tasks more efficiently.

Here are some examples of such technologies:

- Voice-picking systems: Using natural language processing, voice AI systems provide instructions to warehouse employees, guiding them through a picking task. This technology can help increase picking accuracy and reduce order completion turnaround times.

- Wearable devices: AI-based technologies, such as smart glasses and wristbands, can track employee movements and provide instant feedback. This has the potential to enhance workforce efficiency and reduce workplace injuries.

- Support chatbots: Large language model-driven robots are capable of providing instant help and support to employees working in a warehouse. This system can respond to employee queries and provide real-time information by interfacing with the WMS.

- AR/VR headsets: Warehouse workflows can be replicated through augmented reality and virtual reality technologies. This enables new employees to perform complex tasks in a safe, simulated environment. Companies can therefore reduce the time it takes to onboard new workers.

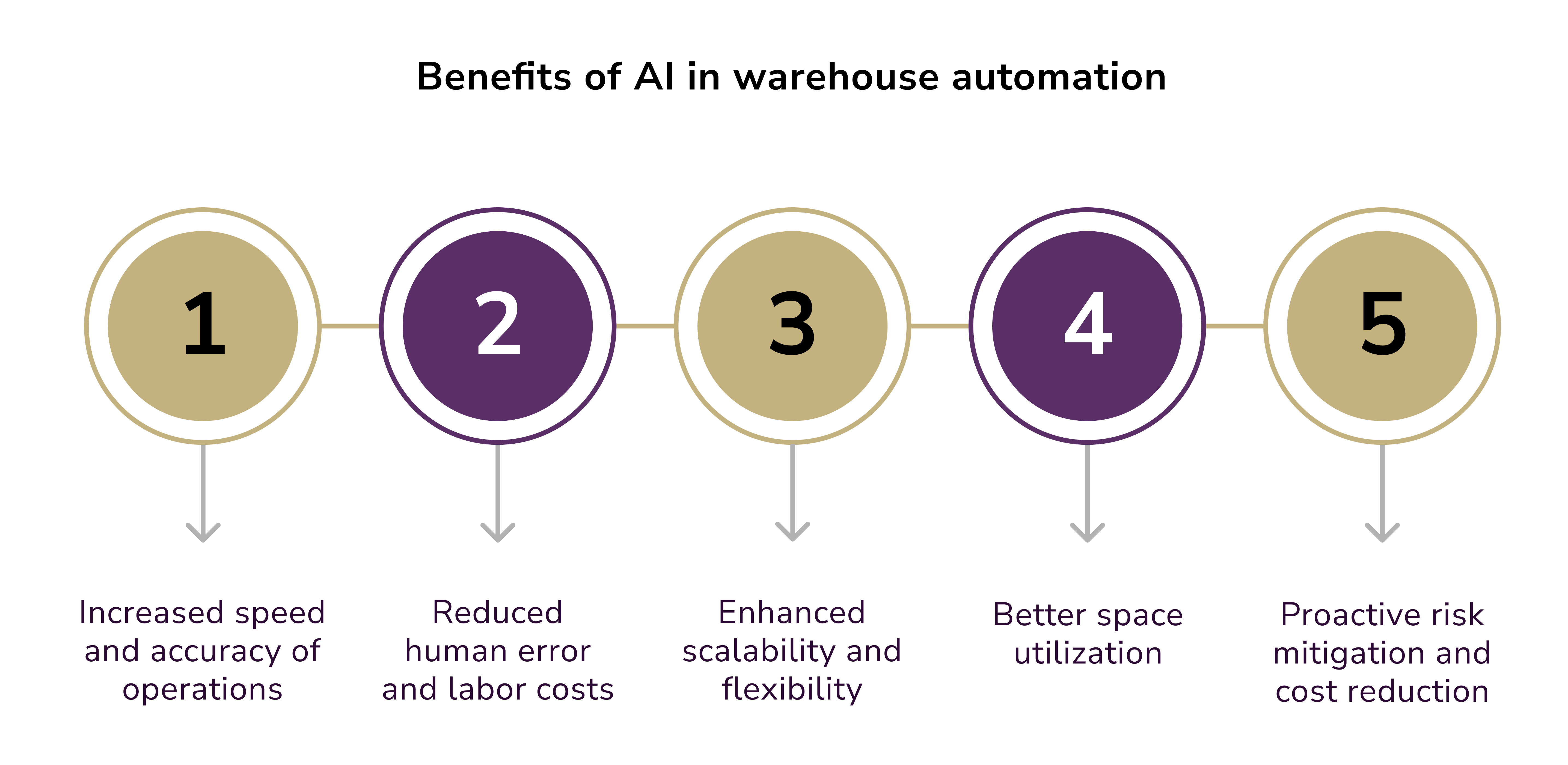

The Impacts of AI in Warehouse Management

Redesigning warehouse operations to incorporate the use of AI technologies can yield tangible results for businesses.

Productivity

Most technologies and process improvements aim at maximizing throughput. Efficiency is one of the most important values to monitor in a warehouse, as it impacts costs and operational speed. AI can streamline and automate order processing, assisting with dynamic slotting and putaway to minimize picking time. For instance, it can suggest where best to position items based on demand, such as relocating high-velocity items to a packing and shipping station.

Order Accuracy

Using computer vision and image processing to scan every item that’s been picked, AI-powered systems can spot mistakes (like mislabeled packages or the wrong product choice). They also identify orders at risk of running late, so managers can intervene and alert customers to potential delays. AI also has a big role in warehouse automation as algorithms can guide autonomous mobile robots to handle items more rapidly and accurately.

Example: Ocado, a British online grocer, employs AI to run its massively automated warehouses. Robots pick and pack groceries with precision, guided by AI programmes. The system facilitates rapid and accurate order fulfillment, including intricate grocery orders. AI also improves space utilization and decreases operational costs.

Forecasting

Forecasting is essential for fulfillment centers to keep the right amount of stock throughout the different seasons. In demand forecasting, AI learns to predict a company's stock needs by analyzing historical data. An AI-enhanced WMS mitigates short and long stock scenarios by informing managers of stockouts. AI systems can also predict the demand for specific products during specific seasons, such as the holiday and back-to-school seasons. As a result, managers can optimize product availability to avoid stockouts during critical periods.

Processing

Warehouse managers continuously seek to reduce the time required to receive, stow, pick, and process items. AI facilitates this by predicting which items are frequently ordered together, helping employees design item bundles to avoid long paths across the warehouse. AI also helps reduce data entry by automatically extracting processing details from invoices and shipping notices.

Footprint Planning

AI can be used to design and optimize the warehouse layout for maximum efficiency of workflow and pick paths. This ranges from organising infrastructure to using minimal space, stocking related items together, to processing tasks faster, mapping optimal picking routes to avoid congestion, through to ensuring materials and equipment flow smoothly.

Equipment Lifetimes

The more data is assimilated, the more powerful AI becomes. When monitoring the health of equipment in a warehouse, AI can look for operational abnormalities in heat, vibration, or throughput. Early detection of such anomalies can help to predict malfunctions or even failures of the equipment. This enables managers to plan for maintenance activity before the equipment breaks down. This is important for the continuity of work and also helps to prolong the life of the equipment.

Example: FedEx employs AI to track the condition of its warehouse machinery, including conveyor belts and sorting machines. Predictive maintenance reduces unexpected equipment failures, downtimes, and interruptions. This forward-looking process not only extends the life of the equipment but also reduces the maintenance costs.

Safety

Most warehouse activities are physical. Physical work in a warehouse can pose safety hazards, making employee safety a big concern. AI can help determine when it is reasonably safe for machines to take over tasks that human workers would otherwise perform. AI can also assist in implementing ergonomic and safety measures, for example, by ensuring that heavy items are not placed on high racks.

Example: DHL has deployed AI-driven robotic arms for piece-picking and leverages predictive analytics to forecast operational disruptions. The robotic arms can perform monotonous tasks with a high degree of accuracy, allowing human employees to engage in more complex tasks. Predictive analytics enable DHL to anticipate delays and proactively reroute shipments and adjust operations to mitigate them, thereby helping ensure on-time deliveries and maintain service-level agreements.

Visibility

Businesses with advanced tech and AI have comparatively higher operational visibility and can make informed and swift decisions to optimize processes like inventory and order management. AI also supports efficient decision-making on production, procurement, and capital allocation by predictive demand forecasting and suggesting maintenance courses of action. Operational inefficiencies, compliance gaps, and improvement opportunities can be detected and described by AI systems working on the business in real time.

Cost Reduction

AI systems provide real-time analytical data for warehouse managers to reduce overspending on utilities, labor, and inventory. AI-based systems with computer vision and monitoring use their knowledge to adapt the environment to occupancy and activity levels, improving resource use and reducing the facility's operational costs. Automation also has a cost-reducing productivity impact by assigning transactional activities like picking, packing, and sorting to autonomous machines and releasing people to higher-value, strategic activities.

Sustainability

Given the volume of electricity consumed by warehouses, many companies are using AI to minimize the environmental impact of their operations. AI systems can reduce electricity use for lighting, heating, and cooling supply by adapting to real-time occupancy. For example, in a data-driven environment, AI can save electricity by avoiding illumination of unoccupied spaces or by adjusting heating to lower or higher levels during non-peak times. AI systems can lower overall energy consumption by improving efficiency during the resource-intensive order picking part of the inventory management.

A warehouse is the heart of the supply chain. The efficiency of this hub directly impacts everything from delivery speed to customer satisfaction. For years, businesses have relied on manual processes and basic automation to keep goods moving. By integrating AI, businesses can finally move beyond simply reacting to demands and start predicting and shaping their operational outcomes.

We, at Impressit, have dedicated teams skilled in AI development and implementation across industries. If you need help with your project, we will gladly help you create the product you envision.

Roman Zomko

Other articles