Predictive Analytics in Logistics Industry

The inherent complexity of the logistics industry means that severe delays and huge monetary losses can occur as a consequence of even the smallest disruptions. Predictive analytics determines the probability of certain possible outcomes by utilizing historical records, statistical operations, algorithms, and machine learning. In logistics, predictive analytics has the power to anticipate demand, potential supply chain disruptions, and optimize delivery routes and inventory management. The ability to synthesize large amounts of raw data and convert it into actionable information can help firms reduce costs and offer affordable delivery rates.

The Strategic Importance of Predictive Analytics in Logistics

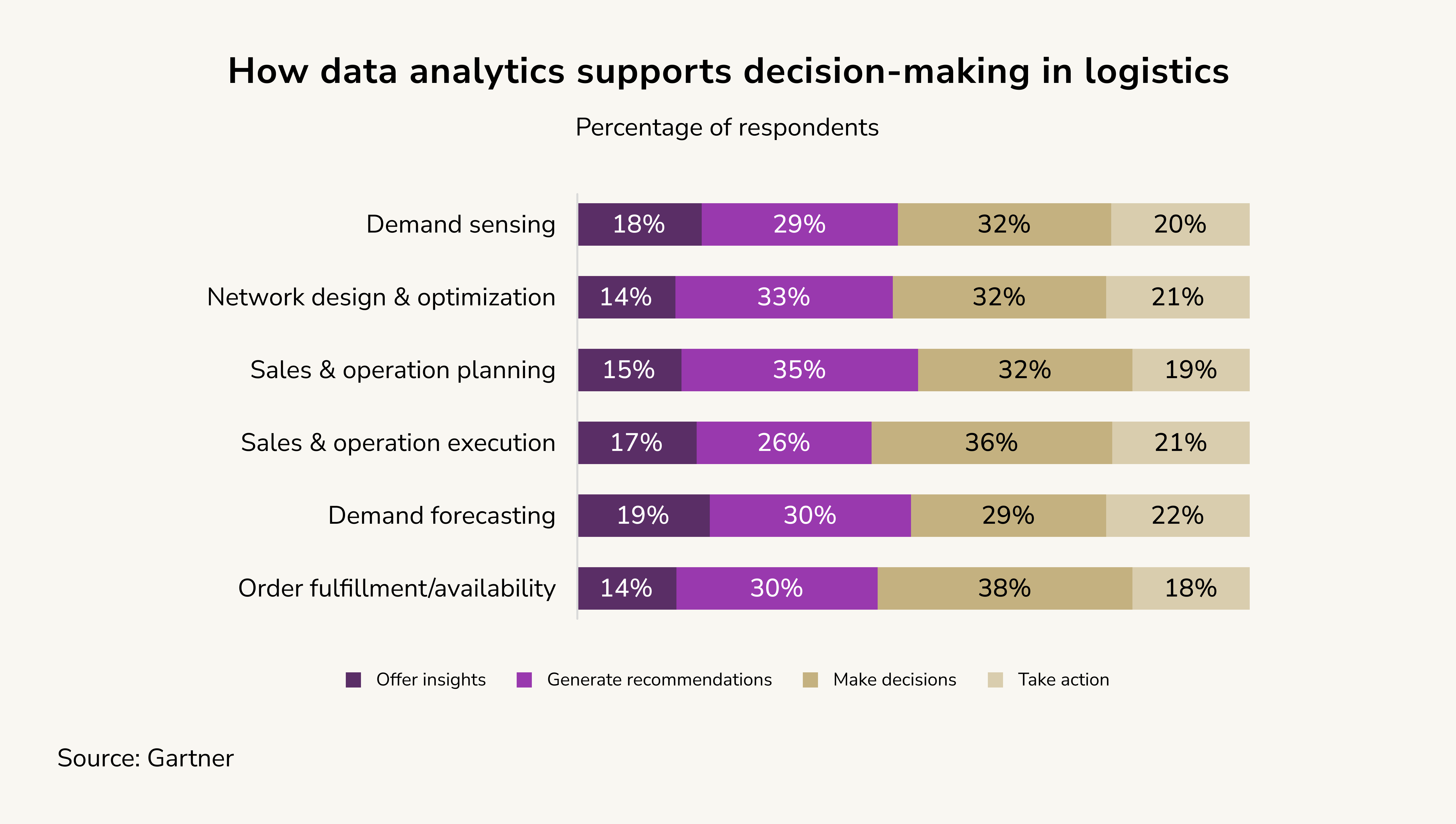

Predictive analytics helps foresee fluctuating customer demand, inefficient routing, and inventory misalignment. By utilizing statistical algorithms and formulating various predictive potential outcomes, organizations can make better supply chain decisions. As per Hyperscience, 98% of logistics leaders say AI is vital for back office operations.

Global logistics services providers utilize ML to automate and dynamically adjust ETAs (estimated time of arrival), thereby decreasing deviation and achieving improvement in predicted arrival times.

- DHL invested $350 million in the MySupplyChain digital operations predictive analytics platform, which focuses on workflow automation, resource allocation, and overall supply chain optimization.

- Amazon's "anticipatory shipping" strategy tries to guess customer purchases based on past transactions, then positions the inventory in the warehouse that is closest to the expected delivery point. This delivery resource optimization allows for quicker order fulfillment.

- UPS has improved real-time route optimization within the ORION (On-Road Integrated Optimization and Navigation) platform. This innovation allows delivery route changes to be adjusted on the fly based on real-time data, fueling efficiency improvements and cost savings.

- Maersk uses IoT sensors and operational automation to enhance the predictability of its operational assets, particularly fleet predictive maintenance, and optimize the repositioning of empty containers.

Predictive analytics is key for modern logistics because it enables companies to plan for uncertainty instead of problem firefighting.

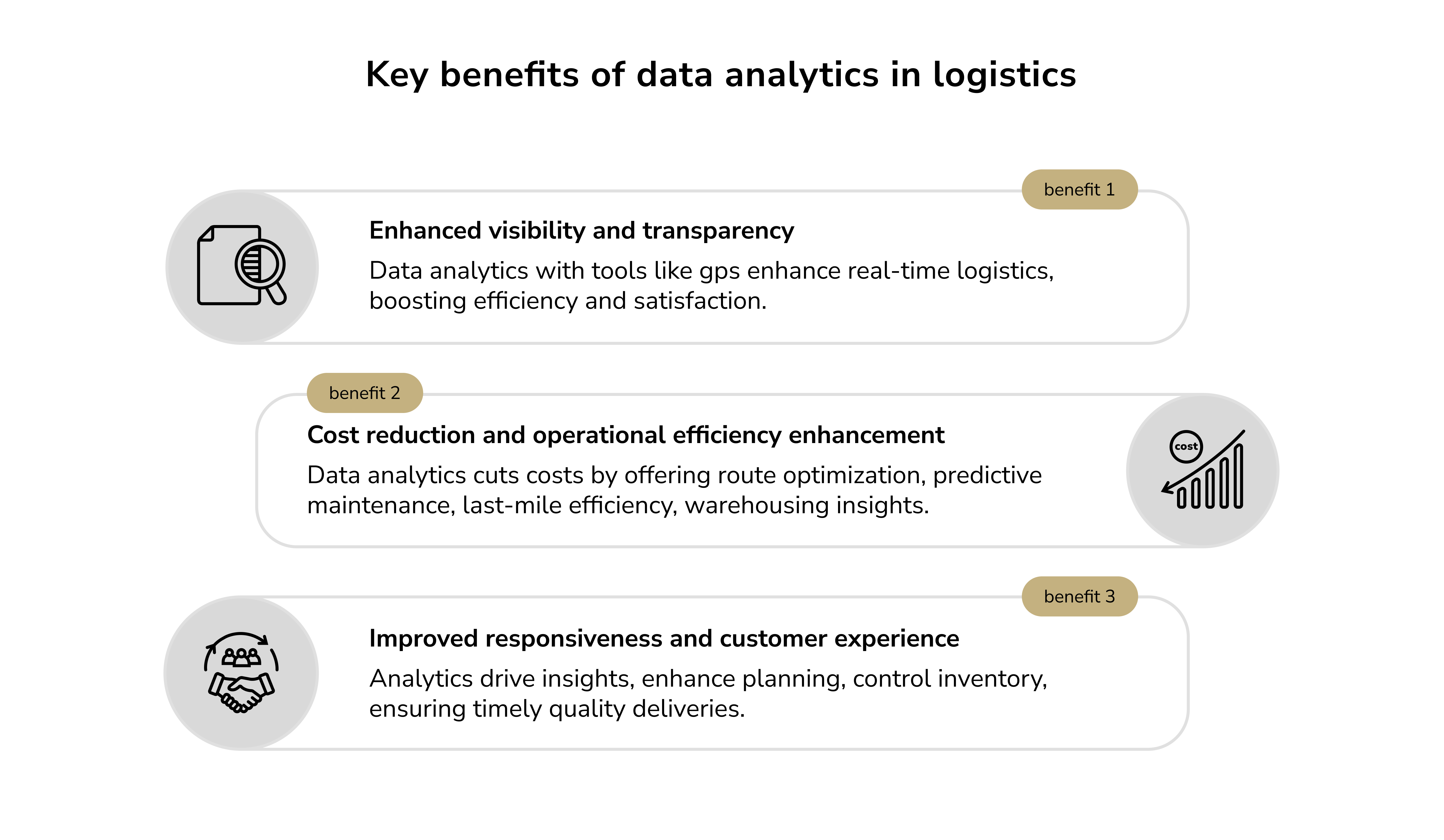

Here are the major benefits that technology provides for the sector:

- Risk and loss reduction: Predictive analytics allows logistics operators to foresee certain problems and cut losses. For instance, algorithms would identify likely congested routes and late shipments, which would allow planners to change routes and schedules ahead of time. Avoiding major delays or mitigating urgent expedites allows for saving costs.

- Efficient customer demand fulfillment: Predictive analytics improves demand forecasting. It helps ensure that customers find the right products in stock and get their orders on time, all without the company overstocking, which is one of the pressing challenges in the logistics industry today.

- Moving from reactive to proactive operations: Logistics operations are often planned in response to last month's data or yesterday's events. Predictive analytics changes this to “what's likely to happen next?" which is what modern supply chains need. This preventive approach results in better preparedness, whether that means staging delivery vehicles before holiday surges or preemptively dispatching maintenance crews before breakdowns.

- Competitive advantage: Predictive analytics in logistics positively impacts an organization's ability to respond to fluctuations in profitability. The technology provides businesses with the ability to quickly respond to changes in shipment patterns and consumer behavior. Firms that use ML can respond to market changes more efficiently compared to those that use spreadsheets and their intuition.

- Complex decision-making optimization: Decision-making support tools are useful for managers who handle variables involving myriad routes, rates, and capacities. For example, an AI-powered predictive tool can assess data and generate a recommended distribution plan for each week.

- Predictive analytics' resilience: The pandemic has underscored the need for systems to be adaptable and responsive. Managers conduct "what-if" scenario analytics to enhance preparation. As supply chains become digitized, opportunities for predictive analytics in logistics become limitless.

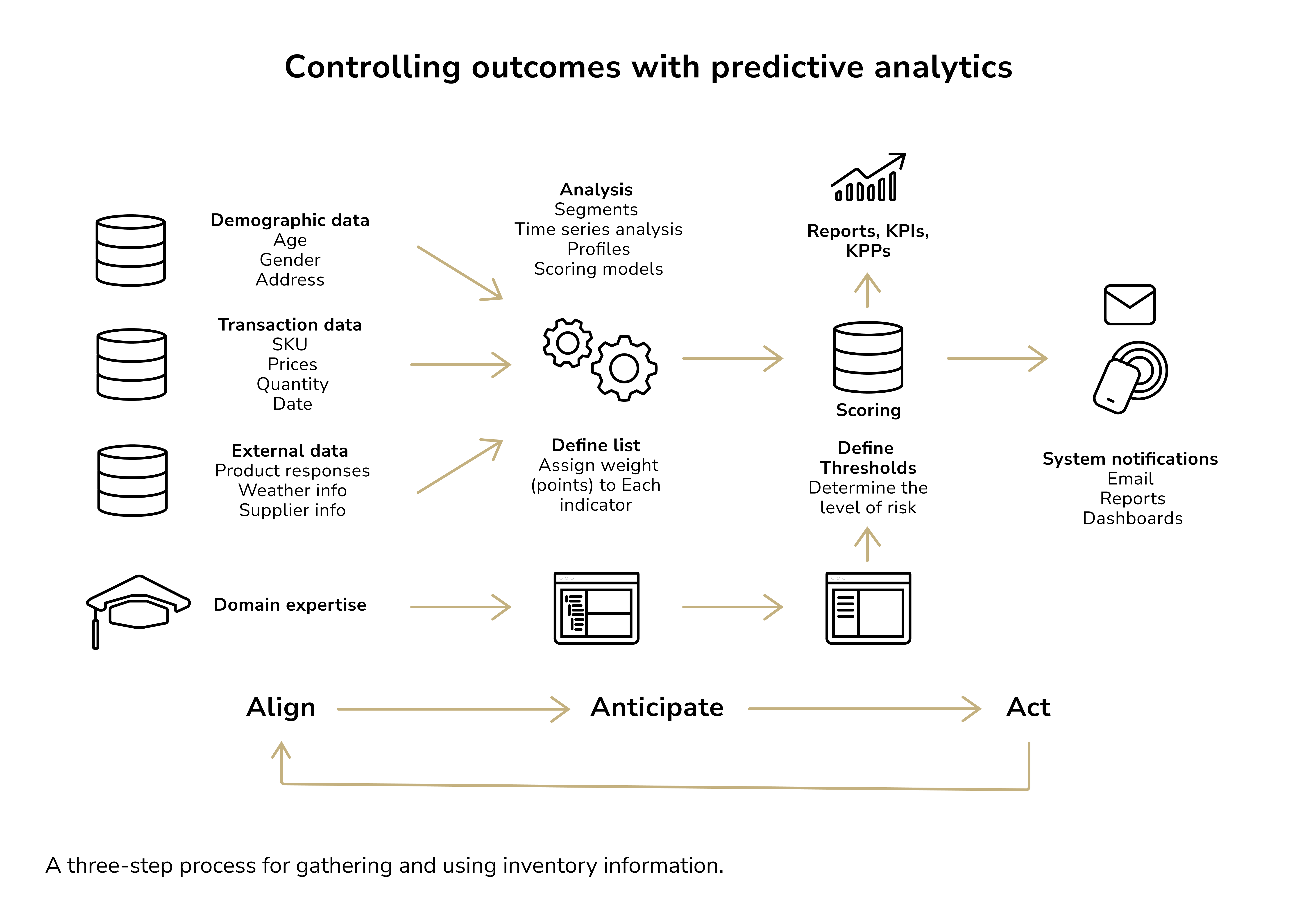

How Predictive Analytics in Logistics Works Across Systems and Operations

Here is a step-by-step look at how predictive analytics works across backend and frontend logistics systems.

Collecting Data from All Touchpoints (Backend)

Gathering data from various points in the supply chain is the first step. This includes data internal to the organization, like records in the Transportation and Warehouse Management Systems (TWMS) and Enterprise Resource Planning (ERP) orders, and data from the external environment, such as weather predictions, traffic data, GPS telemetry, and even social or news data. All these data, both historical and real-time, are stored in a cloud data warehouse or data lake, for example. A logistics company can aggregate years of shipment records, customer orders, scanner data from warehouses, truck sensor data, and more into a single repository.

When dealing with raw data, it almost always needs cleaning and structuring before it can be analyzed. During this portion of the process, data engineers clean the data by eliminating erroneous data, addressing gaps, and reconciling differences across various sources of data. Data also needs to be organized and put into a specific format (for example, making sure time stamps are in the same format and converting to the same unit of measure).

This step, commonly referred to as data normalization, is important to ensure predictive algorithms do not get thrown off by irrelevant data. As an example, if several warehouses store or log product codes in different formats, codes can be changed to a common mapping format. In addition, irrelevant data, outliers, and noise are removed. Many projects spend a large amount of time on this aspect of the project. Data is then typically organized into analytical data. For instance, one analytical table may contain daily shipments per lane. Another table may contain daily inventory levels by SKU.

Training Models on Business Data (Backend)

With clean historical data, a data scientist and a data analyst will work on building predictive models. They will tailor algorithms, such as statistical models, machine learning models (regression, time-series, random forests, neural networks, etc.), and other classifiers, depending on the issue at hand (e.g., time-series models for demand forecasting, classification models for predicting delay yes/no). The model will go through the historical data, learn, and then be tested on known outcomes (this often gets done as a proof of concept to validate the approach).

For instance, a demand forecasting model could be trained using 3 years of sales data and then tested to determine whether it would have been able to predict the last 6 months of data. If not, the model will need to be tuned. It is common to go through many models and select the one that performs the best. More often than not, this is iterative – models are tuned and refined to hit an accuracy target (e.g., a specific Mean Absolute Percentage Error (MAPE) for forecasts). To streamline model training, designers incorporate current, real-time data as the model data to ensure it stays relevant.

This step highly demands experience from site experts and implies that the results the model gets are realistic.

Deploying the Prediction Engine into Live Systems (Backend)

Once validated, the predictive model is deployed into the production environment, which involves integrating it with the live data streams and operational software. For example, the model could be wrapped in an API service that the firm's TMS or control tower software queries to obtain predictions. In a modern environment, this is often in the cloud or built around existing software infrastructure.

Deployment is when the algorithm begins to access real-time data continuously rather than just static historical data, and it is often updated with recent information, such as new orders or sudden severe weather alerts. In deployment, the model is designed to be scalable, support thousands of predictions, and obtain forecasts in real-time. The model functions and integrates with the rest of the IT system as a self-optimizing predictive component.

Operational Dashboards for Displaying Predictions (Frontend)

Making sure that predictions are actionable means conveying them clearly to the users, including planners and managers. This is where business intelligence (BI) dashboards and visualization tools come in. The predictive analytics system provides an output to the user dashboards for forecasts, risk scores, and recommended decisions, which the operations teams use on a daily basis.

For instance, a logistics manager could use a dashboard that shows a map of real-time shipments and any at-risk deliveries and predicted arrival times. Supervisors in the warehouse could access a dashboard that shows forecasted volumes of inbound shipments for the next week. Predictive volumes help supervisors identify when a surge is likely to occur.

These interfaces drill down for details and are available on desktops and mobile devices for personnel in the field. By visualizing predictions, companies ensure that decision-makers understand the insights and integrate them into the planning process. Effective dashboards are updated in real-time as new data is available, providing a live "crystal ball" for the operation and predictive data.

Triggering Automated Responses and Workflows (Frontend + Backend)

One of the most valuable features of predictive analytics is the ability to combine forecasts with automated actions. When predictive thresholds are reached, the system can set off automated workflows. For example, a model predicting a delivery delay of above 90% likely can automatically issue a customer alert via email/SMS and notify the team used to re-routing to take action. On a more proactive note, a warehouse system predicting tomorrow's outbound volume to be twice the volume of the outbound table for tomorrow can automatically request the temps to be scheduled for the day. This type of automated response provides users with action predictions without the need for added human response time.

Applying predictive analytics on the backend through automated processes on the front enables real-time functionality for users. Another example is in inventory. If a system predicts a product will run out of inventory in 5 days, it can automate the purchase order to the supplier for the product (or at least schedule for planner approval). Over the years, companies tend to automate more based on their increasing confidence in the forecasts.

This step essentially constitutes predictive analytics in action: using forecasts to influence decisions or activities within the operations.

Overseeing the Precision and Advancing the Models (Backend)

Predictive analytics is not a "set and forget" practice. At some point, monitoring the model's evolution and recalibrating it becomes necessary. The logistics ecosystem is dynamic, so demand patterns shift, new product lines appear, and external contexts change. Examining forecast error and the metrics describing the proportion of correct and incorrect predictions helps to identify when models need a refresh.

When staleness falls below a certain threshold, scientists can retrain the model using the most recent data and different modeling approaches. Firms should regularly review the processed data, ingest new data sources, and retire obsolete sources.

In the most fundamental sense, this establishes an analytics improvement cycle that is necessary for a robust predictive engine that is both sharp and consistent with the current business reality. It is like keeping a machine in shape. It ensures the analytics system provides sustained value as conditions alter.

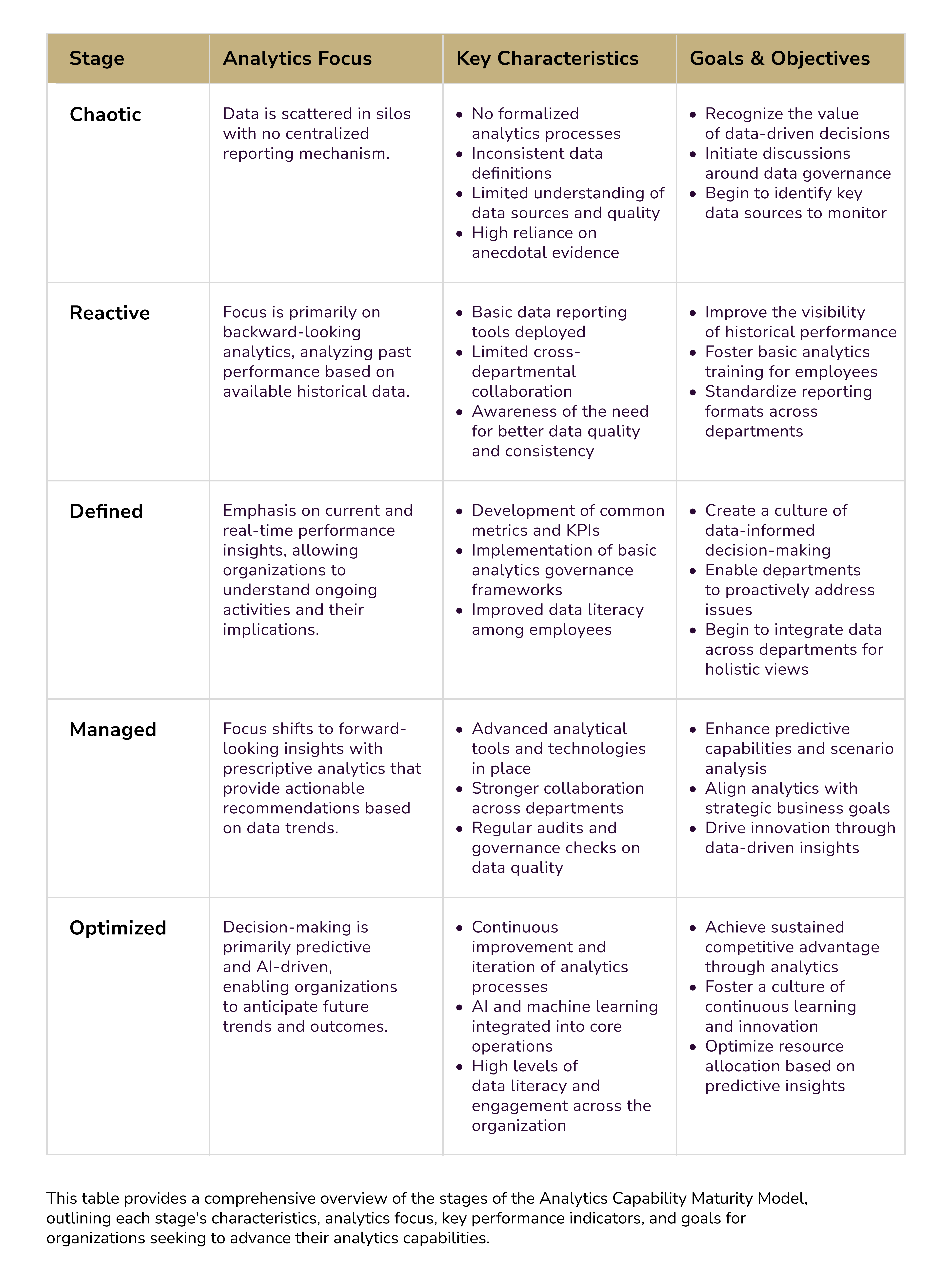

Analytics Capability Maturity Model in Logistics

Analytics capability maturity refers to the progression of an organization's analytics competencies from basic reporting to advanced predictive and prescriptive analytics. Understanding where a logistics company falls on this maturity curve helps in planning the next steps for improvement.

The logistics analytics capability maturity model shows a clear progression:

- beginning with Level 1's reactive reporting of "what happened"

- through Level 2 with a comprehension of "why"

- to Level 3's predicting "what will happen"

- and culminating at Level 4 with understanding "what's the best that can happen and how do we make it so".

It is important for organizations to understand this progression so that the necessary building blocks can be established at each level (for instance, reliable predictive insights can only be gained once descriptive data is established), and to understand that achieving the higher levels does not happen at once, but rather requires sustained effort.

Advancement through these stages typically entails shifts in culture and changes in technology. For many logistics companies, it helps to identify where they stand in terms of maturity. The upper maturity stages (3 and 4) tend to deliver all the transformational benefits, yet those could only be achieved with a solid data foundation, talent, and backing from the top. Some firms might even expand with a Level 5 cognitive analytics, which pertains to self-learning systems and natural language AI. Although that is in the very early stages, the prescriptive optimized state is what most firms are focusing on achieving right now.

Tools and Technologies for Predictive Analytics in Logistics

Predictive analytics in logistics requires various tools and technologies available at different stages of the data pipeline and the analysis process. For predictive logistics solutions, below are some of the tools and technologies, and their relevant examples.

Data Collection and IoT Devices

Logistics companies utilize IoT sensors, telematics, RFID, and several other data capture devices. To enable predictive models to operate with contemporary data, for example, the models that utilize GPS vehicle trackers to produce real-time location and speed data. Moreover, condition data for temperature-sensitive goods and humidity control documentation is generated within storage units that have telematics sensors. During storage, scanners and RFID readers in the warehousing facilities monitor and track inventory movements. Using telematics platforms such as Geotab and Samsara to collate truck sensor data and data-collection IoT hubs from warehouse equipment, predictive systems can analyze data of various volumes.

Data Integration and Cloud Platforms

The vast amounts and extremely diverse types of data from a supply chain require the use of cloud-based data lakes and warehouses that include Amazon AWS, Microsoft Azure, and Google BigQuery. Integration of logistics data from different cloud sources is achieved via ETL (extract, transform, load) processes, while streaming data can utilize middleware tools such as Talend, Informatica, and Apache Kafka. ERP, WMS, TMS, and CRM systems can also be unified for a coherent view of the data. For instance, one integration tool can pull order data from an SAP ERP, integrate it with delivery updates from a TMS, and send it to a Snowflake data warehouse at a designated time each day. Cloud offers the elasticity and processing capabilities to perform advanced analytics on data.

Analytics and Machine Learning Software

The software market has enough data science tools, programming languages, and libraries for building custom predictive models. These include Pandas, scikit-learn, TensorFlow, etc. It also includes predictive analytics tools such as SAS, IBM SPSS, and RapidMiner. For logistics, there are new AI and supply chain AI services, such as SAP’s Analytics Cloud with supply chain modules or Azure's AI services.

Open-source tools like Python and R are highly valued for their flexibility, but are best suited for those with solid coding skills. Most enterprise platforms offer greater integration, more user-friendly interfaces, and ease of use. Some AI-focused logistics startups, such as Transmetrics and ThroughPut.ai, develop predictive demand and capacity planning tools for logistics providers, while Kinaxis and o9 Solutions offer end-to-end supply chain planning that includes predictive analytics.

Optimization and Simulation Tools

The logistics industry frequently requires the use of prescriptive decision support. Software designed for optimization, like IBM ILOG CPLEX or Gurobi, can use predictive analytics, such as anticipated demand or transit times, to create optimal routing plans or load consolidation. Supply chain simulation software, like AnyLogic and Arena, can develop predictive models of various scenarios to evaluate outcomes. These tools can determine the best actions in line with the given forecasts. For instance, a simulation might leverage projected port delays to assess how the network would handle the delays and assist planners in decision-making.

Business Intelligence and Dashboard Tools

Predictive insights are translated via front-end visualization tools. Users can design dashboards for real-time monitoring with BI tools like Tableau, Power BI, QlikView, and certain supply chain control tower dashboards. Logistics teams may utilize a control tower equipped with a feature that outlines key statistics and provides predictive alerts. Numerous logistics software providers (e.g., Oracle, JDA/Blue Yonder, Infor) have begun to include such analytics dashboards with their predictive analytics suite. Users of certain tools may predict warehouse volume and set a threshold to receive alerts. The BI layer is crucial for user adoption, as it is the only layer a user interacts with.

AI-Based Logistics Software

Software solutions in logistics have built-in AI functionality. Take, for example, SAP Integrated Business Planning (IBP) and Oracle SCM Cloud, which each offer machine learning-powered demand forecasting and inventory optimization tools. Llamasoft (by Coupa) enables users to perform scenario planning using its supply chain design software. AI capabilities that support labor forecasting and dynamic routing are embedded in the warehouse and transport management systems for Manhattan Associates and Blue Yonder (formerly JDA). If these tools are appropriate for the company and its needs, they can help carry out the implementation in an accelerated manner since they are optimized for several predictive logistics functionalities.

Cross-Partner Collaboration and Data Sharing Tech

Technology that supports safe data exchange and collaboration is useful since the supply chain usually involves multiple stakeholders. For example, blockchain technologies are being used for real-time, tamper-resistant shipment tracking and supplier data sharing for trustworthy shipment predictive analytics. Beyond integrations for predictive analytics, basic collaboration technologies like APIs and web services allow systems to communicate programmatically, as in the case of a retailer system obtaining demand data from a manufacturer’s system that will be aligned to collaborative demand forecasting and predictive APIs.

Predictive Analytics Setup

For a logistics company, a typical predictive analytics setup might consist of IoT devices, operational data, and other enterprise systems streaming into a cloud data lake via Kafka and other systems integrated with ETL processes. After that, data scientists either incorporate some Python or an AutoML solution and work on model creation in a cloud-based analytics environment on Azure Databricks, which is followed by feeding analytical results back into a SQL data warehouse. Tableau dashboards are used to query that warehouse for the planners, and some results also feed back into the TMS/WMS to perform actions automatically. The variations in the choice of specific tools come from the domain needs, but successful deployments demonstrate model computability, seamless integration, and user interfacing.

As logistics companies acquire more AI competencies, the automation of machine learning (ML) processes and tools (e.g., MLflow, Kubeflow, or cloud ML services) for monitoring and deploying ML systems in production becomes more integrated in the operational workflows to improve predictive analytics. MLOps practices allow logistics companies to manage and version control predictive models and ensure seamless AI integration in daily operations.

Finally, selecting tools often comes down to deciding between development in-house and outsourcing. Some companies build custom solutions if they have unique needs or strong internal talent; others use vendor solutions to leverage proven technology quickly. Often, a hybrid approach is used – for example, using a vendor’s platform for demand forecasting but developing a custom model for something very company-specific, like predicting damage to goods in transit. The toolset should align with the company’s IT strategy, budget, and talent – but with today's technology, even mid-sized logistics firms can access advanced analytics capabilities thanks to cloud and open-source offerings.

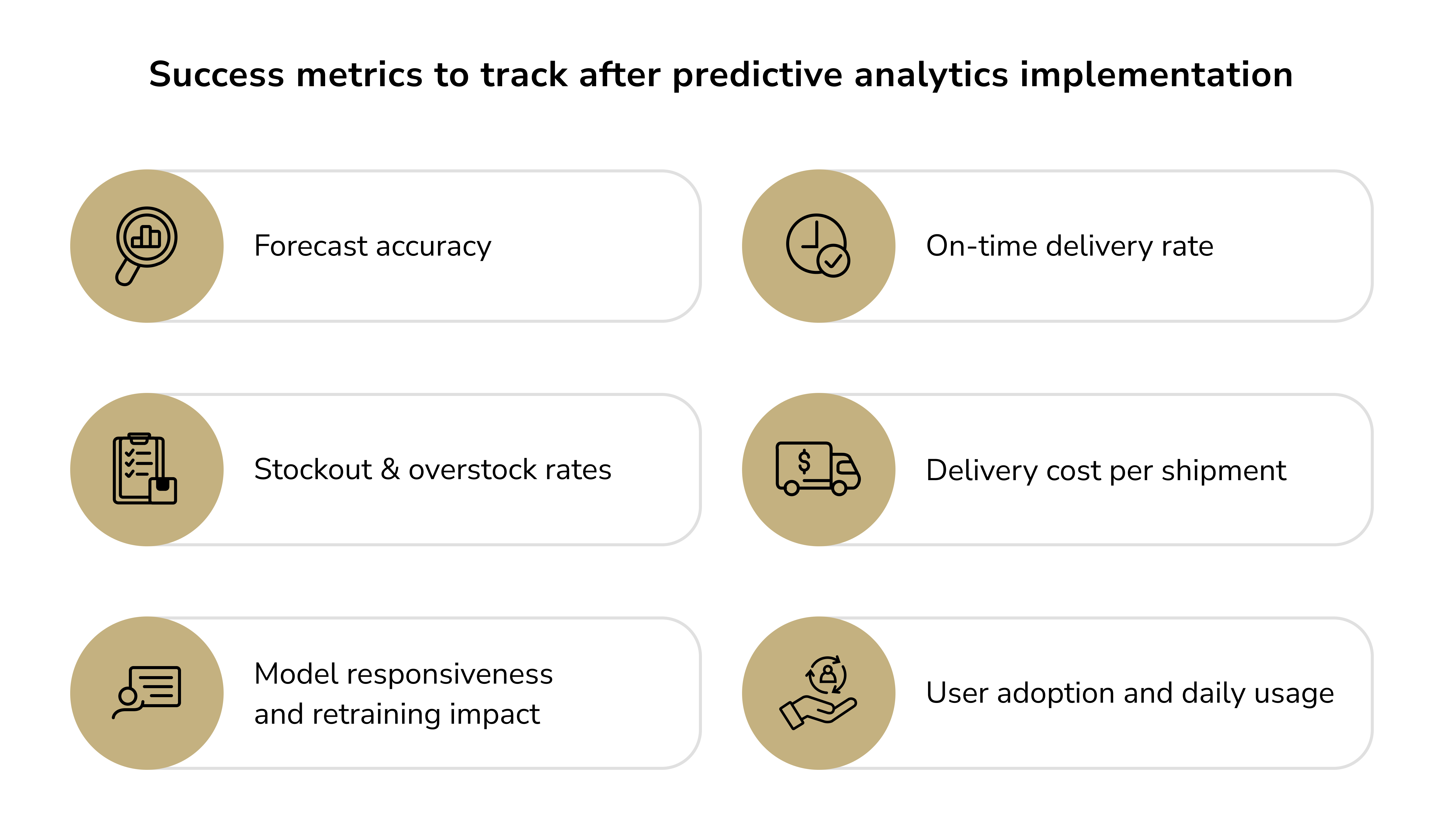

Success Metrics to Track After Predictive Analytics Implementation

To justify the investment in predictive analytics, it is essential to track relevant key performance indicators (KPIs). These metrics provide tangible evidence of the technology's impact on operations and the bottom line.

- Forecast accuracy: The primary measure of a predictive model's success. An increase in demand forecast accuracy directly leads to better inventory management.

- On-time delivery rate: A key indicator of frontend efficiency and customer satisfaction. Improvements here demonstrate the effectiveness of route optimization models.

- Inventory turnover: This metric shows how often inventory is sold and replaced. Higher turnover indicates efficient inventory management and reduced carrying costs.

- Order fulfillment cycle time: The time it takes from order placement to delivery. Reductions in cycle time point to a more efficient and responsive supply chain.

- Cost reduction: Track reductions in operational costs, including fuel, maintenance, and penalties for missed service-level agreements (SLAs). For example, Atlantic Health saved $70 million over three years after implementing a predictive system.

Machine Learning for Custom Logistics Software (Beyond Predictive Analytics)

ML trends bring adaptability, pattern recognition, and cognitive capabilities into logistics software that go beyond straightforward predictive analytics. It can make software smarter at seeing, listening, deciding, and optimizing. Concretely:

- It sees via computer vision to ensure every package is correctly handled and quality issues are caught.

It talks and reads – via NLP, answering queries and digesting documents automatically. - It learns to act – via reinforcement learning and anomaly detection to handle dynamic decisions and safeguard operations.

- It empowers – by giving human workers AI-driven insights and automation to do more with less effort.

Logistics Automation and Robotics

ML enables the automation of warehouses and transport systems, in part, through the automation of computer vision and control systems. For example, automated computer vision allows the identification of package contents, the detection of damage, and barcode scanning. This can potentially boost the speed of sorting and quality control. ML systems are integrating advanced robotic systems that navigate and pick items in warehouses and are more readily available for transformation into self-driving cars and driver-assist systems. These systems make real-time, autonomous decisions.

Reinforcement Learning Applied to Optimization

Predictive models focus purely on anticipation, while reinforcement learning (RL) develops strategies through evaluation and adjustment. In logistics software, RL can address complicated decision-making challenges. An RL agent can, for instance, simulate various strategies and optimize route planning for vehicle dispatching and order picking in a warehouse.

Google is known for implementing RL strategies to optimize the data center cooling process. In logistics, RL can automate dynamic routing and inventory repositioning close to real-time as conditions fluctuate. This way, RL adjusts and optimizes to the ideal solution for the given parameters.

Communication and Document Processing

Logistics contains a large amount of unstructured text, including emails, contracts, customer queries, user manuals, and more. With the implementation of ML and Natural Language Processing (NLP), there is a chance of changing the data recording approach. For instance, Voice AI could help schedule pickups or answer questions like “Where is my shipment?” and driver inquiries. Meanwhile, fully automated chatbots and virtual assistants could take over customer service automation.

NLP could reduce manual data entry by parsing freight contracts, extracting key data from bills of lading and invoices, and other documents. Voice recognition could enable casual queries and problem reporting, helping workers operate warehouses. Companies could reduce the volume of text customs paperwork via ML extraction and validation. They could also streamline overall customer and internal communications by integrating advanced NLP functions into their logistics software.

Quality Control and Anomaly Detection

ML identifies patterns that show when something is wrong, often more rapidly and more sensitively than rule-based systems. Anomaly detection algorithms, for example, can analyze data collected from reefers' sensors to identify signs of a possible malfunction long before it becomes a critical issue. The technology analyzes delivery data to determine whether a delivery route or driver experiences an unusual increase in delays and incidents, and can, therefore, determine whether it needs investigation.

In cybersecurity, as more and more logistics operations are digitized, the most closely relevant ML algorithms conduct anomaly detection on stream network data to identify and thus prevent possible hacks. The technology can oversee complex systems, and when it detects a significant anomaly, it can alert the user. It can prevent issues such as cargo theft, operational failures, or, in the case provided, unusual route stoppages or route deviations.

Segmentation and Personalization

According to multiple sources, logistics providers are becoming more discriminating when designing the service mechanisms. For more focus and differentiated service, machine learning can classify customers or customer shipments into actionable segments. Unsupervised ML clustering techniques could, for instance, facilitate the grouping of orders with similar service requests and delivery patterns. This information could inform more tailored service design, for instance, custom routing or additional services.

From the marketing standpoint, a 3PL could apply ML to classify prospective clients who might require tailored warehousing services versus clients whose requirements may involve cross-docking. This example, while it might appear outside traditional logistics, highlights the importance of ML in business strategy. Likewise, it can offer additional personalized services, such as ascertaining which customers expect a delivery within a shorter 2-hour window or those who are okay with an all-day delivery window.

Ultimately, ML functions as a cognitive assistant for business process automation. For instance, a planner using a custom logistics system may get decision suggestions from machine learning, such as scheduling shipments via rail instead of truck, etc.

Note: Machine learning does not eliminate the human part of work. Instead, it enables humans to make higher-quality decisions in a shorter time frame. As confidence in the system increases, more decisions are able to be safely automated. This allows human planners to concentrate on more strategic aspects of their work.

Final Word

For a logistics company building custom AI software, leveraging ML in ways we described in this article can differentiate its systems by enabling higher efficiency, lower error rates, and new capabilities (like offering customers chat-based tracking, or using cameras for real-time load verification). In essence, ML doesn't just predict the future; it intelligently automates and improves the present operations across the logistics value chain.

Andriy Lekh

Other articles