The Nuances of Healthcare Logistics: A Complete Guide

The logistics that support the healthcare industry are as critical as the medicines and devices they deliver. An efficient, reliable, and compliant supply chain is fundamental to providing quality patient care. Luckily, the rapid pace of technological innovation offers powerful solutions. The IoT provides real-time visibility, while the potential of AI is being explored in automation and predictive maintenance.

These and other technologies we are about to discuss are helping build more resilient, responsive supply chains that can meet the demands of modern healthcare.

How Healthcare Logistics Differs from General Logistics

Healthcare logistics involves a delicate balance of speed, reliability, and stringent quality control. The entire process is governed by a complex web of stakeholders, including manufacturers, logistics providers, healthcare facilities, and regulatory bodies, all working toward the common goal of patient well-being. Failure at any point in this chain can disrupt treatment, increase costs, and, most critically, harm patients.

One of the greatest challenges is regulatory compliance. The healthcare industry operates under a strict set of rules, including Good Distribution Practices (GDP), Good Storage Practices (GSP), and the EU Falsified Medicines Directive (FMD). These regulations are designed to ensure the safety and quality of medical products throughout the supply chain. Compliance requires maintaining meticulous records of everything from equipment maintenance and inventory management to patient cycle times, and non-compliance can result in costly penalties and compromised patient care.

Another significant hurdle is managing complex and sensitive inventory. Many healthcare products, such as vaccines and biologics, are temperature-sensitive and require precise conditions during storage and transit. Balancing inventory levels is a constant struggle; shortages can halt critical treatments, while overstocking leads to waste, especially with products that have short expiration dates. The pandemic underscored this challenge, as demand forecasting for essential items became nearly impossible, leading to widespread disruptions. Furthermore, the security of products such as blood samples and high-value pharmaceuticals is paramount, requiring stringent measures to prevent theft or tampering.

Beyond its focus on medical supplies and equipment, several factors set healthcare logistics apart from general logistics. The primary distinctions lie in four key areas: the nature of the products, the stringency of regulations, the patient-centric focus, and the specialized infrastructure required.

Product Sensitivity and Specificity

General logistics typically deals with durable goods possessing long shelf lives. In contrast, healthcare products are often highly sensitive and require strict handling protocols.

- Temperature control: Many pharmaceuticals, vaccines, and biologics must be maintained within specific temperature ranges to remain effective. A deviation can render them useless or even harmful. This necessitates a secure cold chain for storage and distribution, with ranges including ambient (15-25°C), refrigerated (2-8°C), frozen (-20°C), deep-frozen (-80°C), and cryogenic (below -150°C).

- Inventory management: The First Expired, First Out (FEFO) principle is strictly applied to ensure that products nearing their expiration dates are used first. This practice minimizes waste and prevents the administration of ineffective medications.

- Fragility: Medical products, such as delicate lab equipment, sensitive diagnostic samples, and glass vials, are often physically fragile. They require specialized packaging and careful handling to prevent breakage and contamination.

- Security: High-value pharmaceuticals are frequent targets for theft and counterfeiting. Consequently, healthcare logistics providers must implement secure transport methods, access-controlled facilities, and verified personnel to maintain product integrity.

Regulatory Rigor and Compliance

Healthcare logistics is governed by a complex web of regulations that extends beyond standard logistics laws. The industry is also subject to the regulations imposed on the broader healthcare sector.

- Traceability: To combat counterfeiting and facilitate rapid recalls, regulators now mandate unique identifiers and lot tracking for pharmaceuticals. This requires meticulous documentation and auditing at every stage, including temperature logs, handling records, and chain-of-custody documents.

Patient-Centricity and Urgency

Whereas general logistics serves typical retail consumers, healthcare logistics is directly linked to patient well-being. This direct-to-patient (DTP) model demands discretion, specialized handling, and precise coordination.

The consequences of logistical failures can be severe. A delayed shipment of surgical supplies can delay a critical operation. A compromised vaccine shipment could result in a public health crisis. Time is of the essence, particularly in high-stakes scenarios such as emergency deliveries of blood plasma, just-in-time (JIT) delivery of custom surgical kits, or the swift transport of a donor organ for transplantation.

Specialized Infrastructure and Personnel

The infrastructure for healthcare logistics must meet exacting standards:

- Specialized warehouses: Facilities must be temperature-mapped to ensure consistent conditions. They often include validated clean rooms, refrigerated and frozen zones, and secure vaults for controlled substances.

- Handling equipment: Shipments require specialized equipment, such as refrigerated vehicles and real-time monitoring devices. Validated, temperature-controlled packaging systems, whether active (powered) or passive (insulating materials), are also essential.

- Skilled personnel: The entire process is managed by highly trained personnel proficient in GDP, product-specific handling protocols, and regulatory compliance, ensuring the smooth and safe operation of the supply chain.

Key Components of the Healthcare Logistics Process

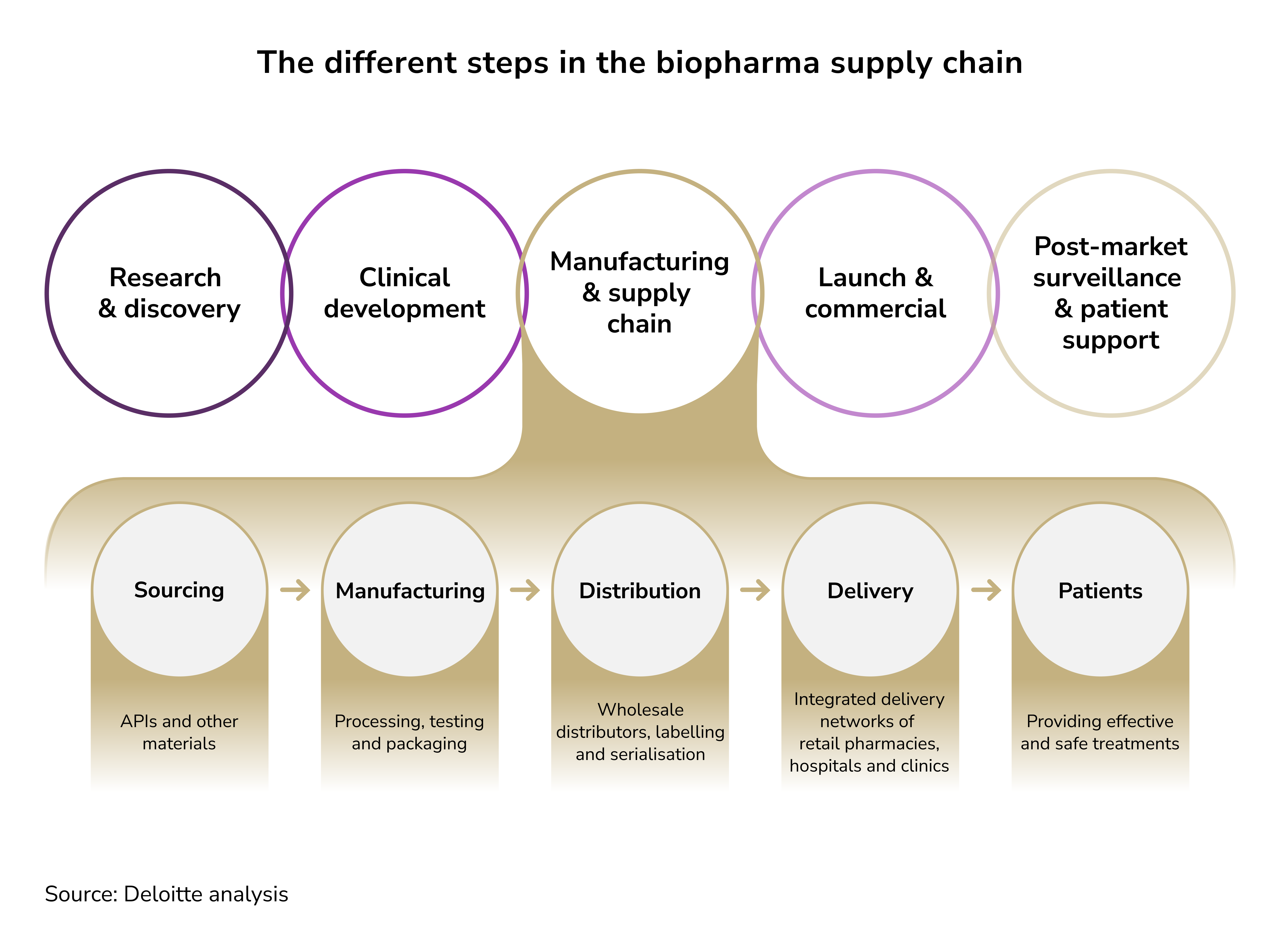

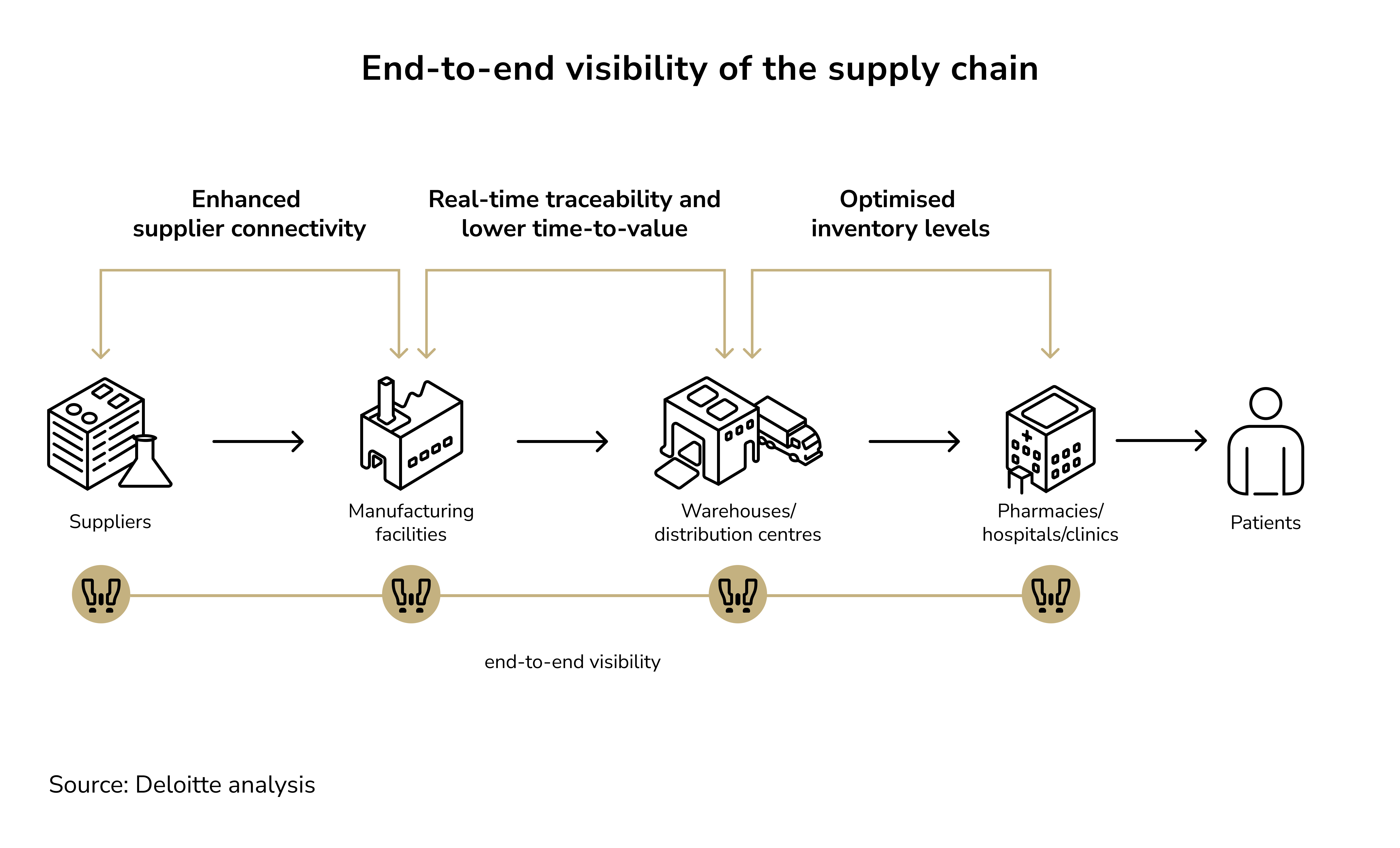

An efficient logistics system allows healthcare providers to respond effectively to emergencies, adapt to fluctuating demands, and minimize waste. While the supply chain oversees the entire lifecycle of a product, logistics focuses on the proper shipment and handling of goods. Together, they form the operational backbone of the healthcare sector.

The success of healthcare logistics relies on the coordinated efforts of several key stakeholders:

- Manufacturers: Entities that develop and produce pharmaceuticals, medical devices, and other essential supplies.

- Logistics providers: Companies are responsible for the transportation, warehousing, and tracking of medical products.

- Healthcare facilities: Institutions that depend on timely and accurate deliveries to provide continuous patient care.

- Regulatory agencies: Bodies that enforce compliance with safety, quality, and legal standards.

- Patients: As the ultimate beneficiaries, patients rely on a seamless logistics system for their care.

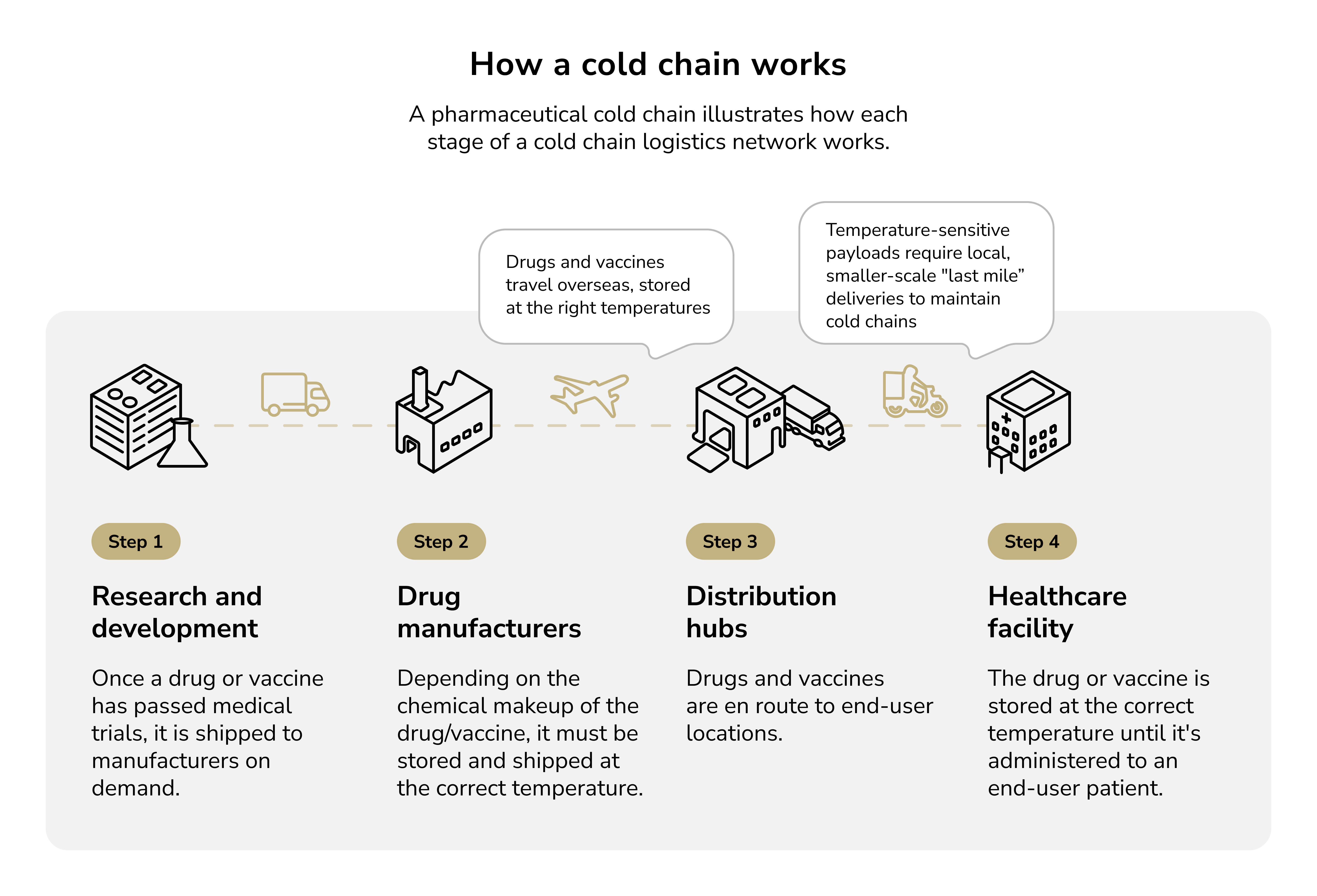

How a Cold Chain Works

The cold chain is a specialized segment of the supply chain dedicated to products that must be kept within a specific temperature range. Over 95% of all approved biologics and 90% of all vaccines are temperature-sensitive, making the cold chain indispensable for modern healthcare. A failure at any point can render these products ineffective or even harmful. The industry loses an estimated $35 billion annually due to improper handling of temperature-sensitive shipments, highlighting the financial and medical stakes involved.

A cold chain is an end-to-end system of storage and transportation designed to maintain product integrity. This involves several key components:

- Specialized packaging: Products are shipped in either passive containers, which are insulated boxes with coolants like dry ice or gel packs, or active containers that use electrically controlled cooling systems for more precise temperature management.

- Climate-controlled transportation: Refrigerated trucks (reefers), railcars, and cargo containers on ships and aircraft are used to transport goods over long distances while maintaining a stable environment.

- Temperature-controlled storage: Warehouses and distribution centers are equipped with climate control systems to store products at required temperatures, which can range from controlled room temperature (15°C to 25°C) all the way down to cryo storage (-160°C).

The process requires constant monitoring. Experts in cold chain management use specialized vehicles and technology to safeguard sensitive items, ensuring their quality and efficacy from the moment they leave the manufacturer until they reach the patient.

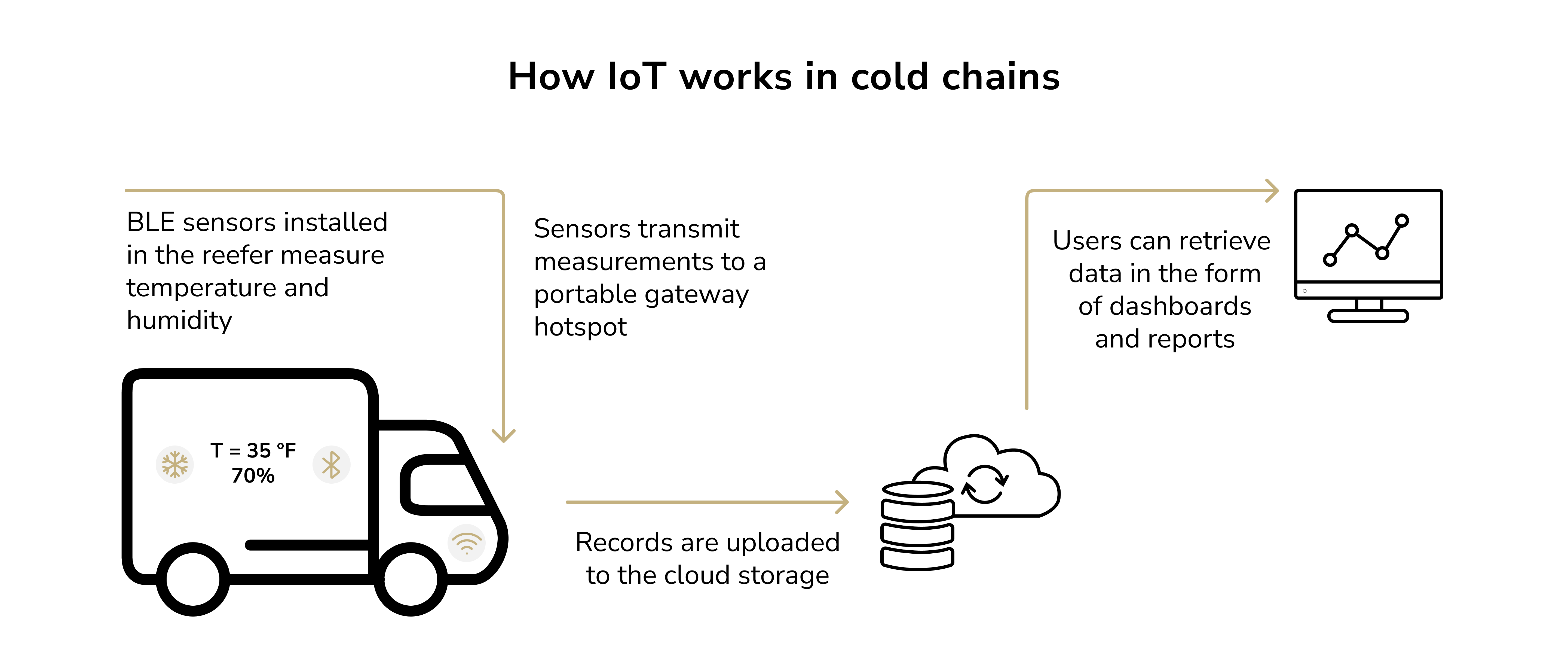

IoT in Cold Chain Management

By embedding sensors into shipments and storage units, logistics providers can monitor conditions in near real-time, transforming a reactive process into a proactive one. IoT-enabled sensors, often using Bluetooth technology, collect and transmit data on temperature, humidity, and location to a central cloud platform. If a deviation from the predefined temperature range occurs, the system automatically sends an alert to the responsible parties.

Beyond immediate alerts, the data collected by IoT devices is a valuable resource for long-term improvement. Machine learning algorithms can analyze this data to identify recurring patterns of temperature deviations, helping to pinpoint bottlenecks or inefficiencies in the supply chain. This analytical capability enables companies to optimize routes, refine handling procedures, and improve overall operational performance. Furthermore, IoT sensors can be used for predictive maintenance on refrigeration equipment, alerting staff to potential failures before they happen and preventing costly temperature breaches.

Healthcare Logistics Management

The management of the global healthcare logistics and supply chain process can be segmented into three main parts:

- First-mile logistics: This stage is primarily driven by pharmaceutical companies and medical equipment manufacturers. Upon receiving orders, these entities ship their products to centralized distribution centers.

- Middle-mile logistics: This segment involves transporting products from manufacturers to distribution centers and then to healthcare facilities such as hospitals, clinics, and pharmacies. In certain instances, healthcare products may be procured directly from the manufacturer, bypassing this step.

- Last-mile logistics: The final stage of the healthcare supply chain involves delivering products to the end-users. The rise of online pharmacies, particularly in the post-pandemic landscape, has become a significant factor in fulfilling this final step.

Historically, healthcare supply chains operated in a decentralized manner, with individual hospitals managing their own procurement and inventory. This fragmented approach often resulted in higher costs for patients and increased errors in supply management.

In the contemporary model, healthcare logistics has shifted towards a more centralized and collaborative framework. This integrated approach enables the sharing of information and resources, thereby reducing operational costs and improving accessibility.

Note: As delivery timelines shorten, healthcare providers are increasingly partnering with 3PL and fourth-party logistics (4PL) firms. Technology is a critical enabler in this evolution. Advanced logistics software automates processes such as ordering, tracking, and demand forecasting, ensuring that providers have the necessary resources when required. By automating labor-intensive manual tasks, these technological solutions optimize logistical functions, minimize errors, and ensure the seamless operation of the healthcare supply chain.

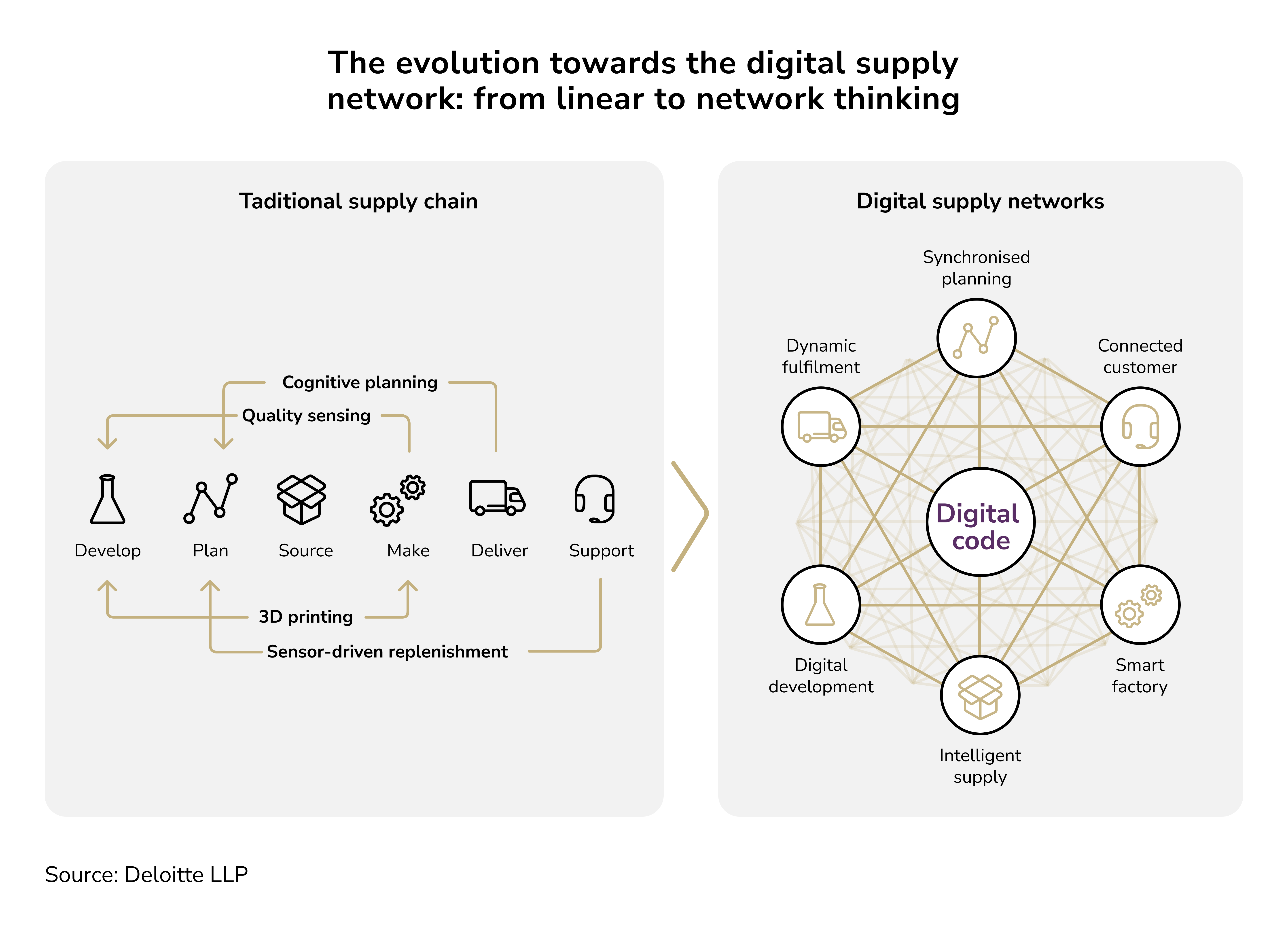

How Modern Technologies are Enhancing Healthcare Logistics Management

The digital transformation of healthcare has inevitably extended to logistics, with cutting-edge solutions now offering enhanced speed, intelligence, and reliability. These innovations address common challenges in the logistics industry, such as operational delays, inefficiencies, and security vulnerabilities, while simultaneously improving transparency and accuracy.

Real-Time Tracking

Real-time tracking technologies provide healthcare providers with constant visibility over their shipments. Utilizing GPS and IoT devices, these systems ensure complete transparency and significantly reduce delays, both of which are critical for time-sensitive deliveries such as medications or organs for transplant.

Example: IoT-enabled sensors can monitor the temperature and humidity within a shipping container in real time, ensuring that vaccines and other biologics maintain their efficacy throughout transit. Any deviations from the required temperature or route are detected immediately, allowing providers to address the issue before it escalates.

AI-Driven Analytics

Predictive analytics in logistics can anticipate when inventory levels are nearing depletion and automatically trigger a reorder, thereby preventing both stockouts and overstocking. Furthermore, AI can identify patterns, such as peak demand periods, enabling logistics providers to plan their resources more effectively. This proactive methodology saves time, minimizes waste, and ensures that essential medical supplies are always available.

Example: The biopharma supply chain generates vast amounts of data that have historically been underutilized. The application of AI to analyze this data is crucial for enabling real-time decision-making, improving operational efficiency, and ultimately developing a cost-effective, nearly autonomous, and successful supply chain.

Automation and Robotics

Automation and robotics have significantly increased the efficiency of medical warehousing and delivery operations. In warehouse environments, automated systems can sort, pack, and manage inventory with high precision, minimizing human error and boosting productivity.

AI-powered robots designed for tasks like picking and placing items can free up human workers to focus on more complex roles. Moreover, the deployment of autonomous delivery vehicles and drones is being explored for urgent last-mile deliveries, especially to remote or underserved areas. These technological advancements are set to reduce labor costs, improve accuracy, and elevate overall operational efficiency.

IoT for Proactive Temperature Monitoring

As previously noted, temperature regulation is a primary challenge in healthcare logistics, particularly during the final stages of delivery, where temperature fluctuations are most frequent.

The use of specialized equipment for storage, packaging, and transportation is fundamental. However, digital technologies also provide significant value by enabling continuous monitoring of temperature, humidity, and sometimes vibration. This monitoring supplies stakeholders with the necessary information to confirm that a safe and stable environment is maintained.

Data Loggers

Data loggers are devices placed within containers or storage areas to record temperature data at predetermined intervals. To retrieve a comprehensive history of storage and transit conditions for compliance and quality assurance, these devices must be scanned. While data loggers are a cost-effective solution, they do not offer real-time monitoring capabilities. Consequently, their use is typically reserved for non-critical shipments, such as standard pharmaceutical products.

IoT Infrastructure

A more advanced solution involves an IoT infrastructure that uses Bluetooth Low Energy (BLE) or other sensor types. This system consists of connected devices attached to containers or packages, which collect temperature and location data in near real-time. This information is transmitted wirelessly to cloud storage for processing. From there, the data can be accessed on demand or sent as live updates to a user-facing application or platform.

The primary benefit of real-time monitoring is the system's ability to generate automatic alerts when there are deviations from specified temperature ranges or other conditions, facilitating immediate corrective action.

ML

Furthermore, machine learning (ML) can be applied to analyze the collected data and identify patterns of deviation. For example, if breaches in temperature occur consistently at a specific point in the supply chain, ML can help identify bottlenecks or process inefficiencies. This analysis enables operational improvements, thereby reducing the frequency of costly incidents.

Predictive Maintenance for Equipment Support

Another method for preventing temperature breaches is to ensure that all storage equipment, including coolers, freezers, and ice machines, operates correctly at all times. Like any machinery, this equipment requires regular maintenance and repair.

A predictive maintenance approach can be employed to anticipate repair needs and reduce downtime. Similar to temperature control, this involves an IoT infrastructure where connected sensors continuously monitor equipment health. The system analyzes the collected data and alerts maintenance personnel about necessary actions.

Inventory Software for Expiry Management

To effectively manage the expiration of medical products, it is beneficial to combine practical methods like inventory rotation and the First-Expired, First-Out (FEFO) approach with inventory management software. This integration automates parts of the workflow, enhancing both speed and accuracy.

Asset tracking solutions such as barcodes, RFID, or BLE tags can capture crucial product information, including production and expiration dates, lot numbers, location, and status. By consolidating this data into a single system, it becomes possible to track product expiry dates and identify which items require priority movement. Automated alerts can also be configured to notify staff of upcoming expirations, allowing for timely action.

Telematics and GPS for Real-Time Tracking

For time-critical medical shipments, GPS tracking technology provides real-time location data and peace of mind. For ground transportation, telematics devices installed in vehicles can supply this information. For air or sea shipments, tracking data can be obtained from the carrier, often through their website. For more detailed, real-time updates, direct integration with the carrier's system can provide automatic status notifications.

Quality Management Software for Compliance

Regulatory bodies provide guidelines for all aspects of logistics, including warehousing practices, temperature monitoring, disposal procedures, and reporting. These regulations are subject to change, complicating compliance efforts. A quality management system (QMS) can be implemented to ensure consistent adherence to all essential healthcare provisions.

A QMS is a digital platform designed to help healthcare organizations manage and improve the quality of their services and operations. Its features support quality assurance, compliance, risk management, and performance improvement. Key features related to logistics include:

- Documentation management: Ensures quality standards, policies, and procedures are current and accessible.

- Compliance management: Tracks regulatory changes to align logistics practices with current standards.

- Risk management: Provides tools to identify, assess, and manage risks, prioritizing them based on their potential impact.

- Supplier management: Helps manage supplier qualifications, performance evaluations, and quality audits.

- Audit management: Supports the planning, execution, and documentation of internal and external audits to facilitate continuous improvement.

Other digital tools can also enhance supply chain operations. For instance, automated sorting systems improve the speed and accuracy of picking and packing, while access control systems restrict the handling of sensitive shipments to authorized personnel.

To select the appropriate set of tools, an organization must first identify its primary pain points and inefficiencies. Once implemented, the software should be configured to address these specific needs. For optimal efficiency, all IT components should be integrated into a unified structure to enable seamless information flow, end-to-end visibility, and comprehensive data analytics.

AI Automation for Healthcare Logistics

Business process automation is a key driver of efficiency and accuracy in any industry, especially in healthcare logistics. By automating repetitive and manual tasks, organizations can reduce the risk of human error, lower operational costs, and free up employees to focus on more complex, value-added activities. In fact, 92% of healthcare CIOs plan to use AI and machine learning to drive automation by 2025.

In warehouses, automation is transforming how goods are handled. Automated sorting systems can process thousands of items per hour with near-perfect accuracy. Automated Guided Vehicles (AGVs) and Autonomous Mobile Robots (AMRs) are used to transport goods within a facility, expediting processes and reducing the physical strain on workers.

Automated procurement systems are another area of growth. These systems can analyze purchasing data to identify cost-saving opportunities, negotiate better supplier deals, and streamline the entire purchasing process. For instance, an AI-driven system can automatically reorder supplies when inventory levels fall below a certain threshold, ensuring that hospitals always have what they need without manual intervention. The use of autonomous delivery vehicles and drones is also being explored for time-sensitive, last-mile deliveries, especially in remote or underserved areas.

GenAI for Intralogistics

While traditional AI excels at analyzing existing data, GenAI can create new content, such as optimized warehouse layouts, simulated delivery schedules, and even training materials for logistics staff.

One of the most promising applications of GenAI in intralogistics is for demand forecasting and inventory optimization. GenAI can also be used to simulate and optimize complex logistical processes. For example, it could generate thousands of different warehouse layouts and workflows to identify the most efficient configuration. It can also create dynamic routing plans for AMRs based on real-time conditions within the facility.

As the technology matures, GenAI is poised to become a powerful tool for creating smarter, more adaptive, and more efficient healthcare logistics operations. However, healthcare professionals should familiarize themselves with common GenAI security risks to prevent patient data breaches.

Healthcare Logistics Software Development

Building a successful healthcare logistics platform requires integrating several key technological components. Each feature addresses specific challenges within the healthcare supply chain, from maintaining product integrity to ensuring regulatory adherence.

IoT for Condition Monitoring

IoT sensors can be attached to containers and packages to monitor variables like temperature, humidity, and vibration. All collected data is transmitted wirelessly to a central cloud platform, providing real-time visibility into shipping conditions. This constant stream of information allows logistics managers to identify potential disruptions early and take corrective action before a product is compromised.

GPS Tracking and Route Optimization

The timely delivery of medical supplies is often critical. GPS tracking, integrated into logistics software, offers real-time location data for every shipment. Telematics devices installed in vehicles transmit this information, which is essential for ensuring safe, fast, and cost-efficient deliveries.

Note: Modern healthcare logistics software goes beyond simple location tracking. GPS data integrated with route optimization and load planning features allows medical organizations and logistics providers to determine the most efficient delivery routes, consolidate shipments to reduce costs, and provide accurate estimated times of arrival. This level of control and visibility is fundamental to a well-managed healthcare supply chain.

Predictive Equipment Maintenance

Predictive maintenance, powered by IoT, offers a proactive approach to equipment management. Connected sensors continuously monitor the health and performance of coolers, freezers, and vehicles. This data is analyzed to predict when maintenance is required, thereby alerting staff before a serious issue occurs. This strategy minimizes the risk of costly disruptions and ensures that the cold chain remains unbroken.

Shelf-Life Management

Asset tracking solutions, such as barcodes and RFID tags, are central to effective shelf-life management. These technologies capture critical product information, including production and expiration dates, lot numbers, and location details. By consolidating this data within a single software system, organizations can track product shelf-life with precision. The software can be configured to identify items that require prioritized movement and to send automated alerts as expiration dates approach, enabling proactive inventory management.

Inventory Level Management

Advanced inventory management features integrated into logistics software can help strike an inventory balance. By tracking usage rates and leveraging predictive analytics to forecast future demand, healthcare organizations can maintain optimal stock levels. This data-driven approach ensures that essential supplies are consistently available without the financial burden and waste associated with overstocking. Automated workflows can trigger reorder notifications when stock levels fall below a predetermined threshold, streamlining the procurement process.

Routine Task Automation

Automating routine processes can significantly reduce labor costs and improve operational efficiency. By automating order entry and replenishment, for example, staff are freed from manual data entry and can focus on higher-value activities like strategic planning and customer service. This shift leads to improved service quality and a more efficient allocation of human resources.

Compliance Features

A robust software application can help organizations effectively manage their compliance obligations. Key features should include tools to track regulatory changes, manage supplier qualifications, and maintain up-to-date quality standards and procedures. The software can also facilitate compliance audits by providing a centralized repository for all relevant documentation and process records, ensuring that the organization is always prepared for regulatory scrutiny.

Security Features

Security must be a foundational component of the software architecture. This includes implementing strong encryption for data both at rest and in transit, multi-factor authentication to verify user identities, and role-based access controls to ensure that users can only access information necessary for their roles. Secure APIs are also essential for allowing authorized systems to communicate without compromising security. Regular security audits and software updates must be part of the software development lifecycle to address emerging threats and maintain compliance with data protection regulations.

The Imperative of Traceability in Healthcare

For medical device distributors, traceability is essential for several reasons. It is a critical mechanism for ensuring patient safety. In the event of a product recall, a robust traceability system allows distributors to quickly identify and isolate affected devices, preventing their use and minimizing potential harm to patients. It also helps prevent expired devices from entering the patient care environment.

Furthermore, the medical device industry is highly regulated. Regulatory bodies such as the U.S. Food and Drug Administration (FDA) require distributors to maintain detailed records of all devices they handle, including lot numbers, serial numbers, and other identifying information. Effective traceability systems are necessary to meet these compliance requirements and avoid significant legal and financial penalties.

What is Required for Effective Traceability?

Implementing an effective traceability system is a multifaceted endeavor that requires a combination of technology, standardized processes, and trained personnel.

From a technology standpoint, distributors must invest in systems capable of capturing, storing, and managing detailed data for each device. This includes inventory management software, barcoding or RFID scanning systems, and data analytics tools. These technologies work in concert to create a digital record of a device's journey through the supply chain.

Equally important are clear, standardized processes. Velosio notes the need for standardized lot and serial numbers and systematic procedures for tracking device movement. All stakeholders in the supply chain must adhere to these processes to ensure data consistency and accuracy.

Final Word

Investing in custom healthcare logistics software development is a strategic decision that can yield substantial returns. By integrating the features discussed above, organizations can build a system tailored to their specific operational needs. This leads to enhanced efficiency, as automation and optimization reduce manual effort and operational costs.

Improved accuracy in inventory management and forecasting minimizes waste and prevents stockouts, directly impacting the bottom line and the quality of patient care. Furthermore, the enhanced visibility and control provided by such software empower organizations to be more agile and responsive to the dynamic demands of the healthcare market. Ultimately, a well-designed healthcare logistics platform is not just an operational tool but a competitive advantage that supports growth, ensures compliance, and safeguards patient well-being.

Victoria Melnychuk

Other articles