RPA in Logistics: Part 2. Implementation

In the first part of this article, we covered the business value and use cases of RPA in logistics. This part presents the main stages of RPA implementation for logistics invoice processing, common issues, and tips to keep bots secure and compliant.

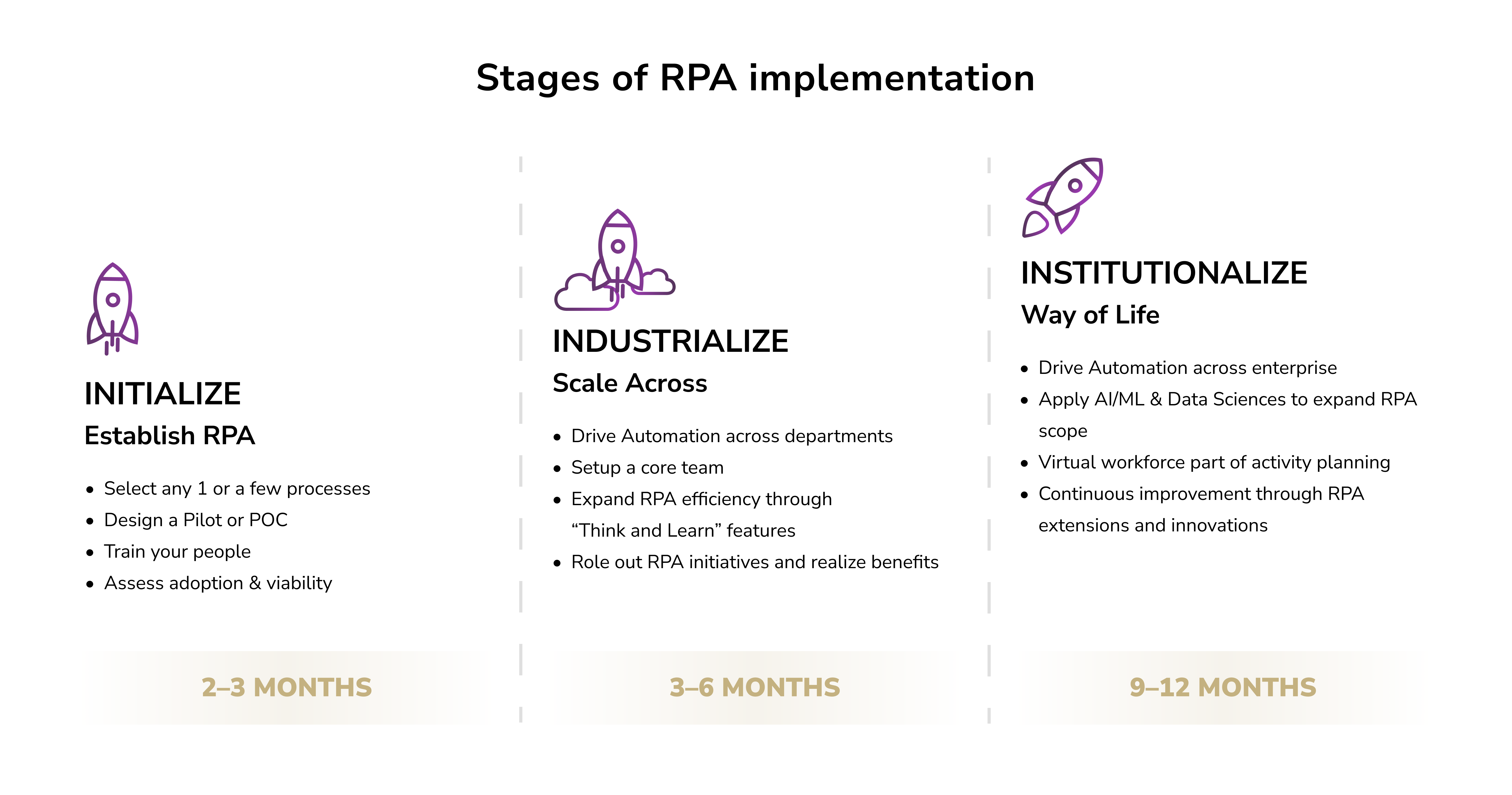

RPA Implementation Phases

For logistics businesses, the goal is not to automate everything, but to identify swivel-chair processes, i.e., tasks where a human acts as a bridge between two disconnected systems (taking data from an email and entering it into a database). These are the high-value targets for robotic simplification.

For instance, Levi Strauss & Co. automated 25,000 hours of work through 45 of its internal bots. These bots enabled the logistics team to process higher volumes without additional manpower by taking over data entry and validation.

Here are some strategic implementation recommendations:

- Start with swivel-chair processes: target those where employees manually move data between two disconnected systems (e.g., Excel to TMS). These offer the highest immediate ROI.

- Don't just automate, optimize: Before applying RPA, map the process. Automating a bad process only speeds up inefficiency. Eliminate unnecessary steps first.

- Focus on the happy path: Create bots that can automate at least 80% of regular transactions (the happy path). Allow people to handle 20% of the complex exceptions. This decreases development time and cost.

- Measure time-to-value: Unlike complex ERP implementations, RPA projects should show value in weeks. If a pilot takes more than 3 months, the scope is likely too broad.

Now, let's map out the implementation process in detail.

1. Select Processes to Improve with RPA

Not all business processes are suitable candidates for automation. Best-practice initiatives in logistics start by focusing on very manual, highly repetitive, rules-based activities with a low exception rate. These "quick wins" are crucial for demonstrating the value of RPA and building momentum for broader adoption.

Some of the critical factors for selecting initial processes include:

- High volume and frequency: Look for "swivel-chair" processes in which employees manually rekey data between systems (e.g., from an email to a TMS).

- Rules-based logic: Tasks that follow a clear, consistent set of rules are ideal for automation, as bots excel at executing predefined instructions.

- Structured data inputs: Processes that rely on structured digital data (such as spreadsheets, databases, or digital forms) are easier to automate than those that involve unstructured or physical data.

Important: Choose processes that are mature and not expected to change significantly in the near future. Automating an unstable process can lead to constant rework and maintenance.

Common starting points for RPA business process automation include data entry, report generation, invoice processing, and employee onboarding. As an example, we will describe the RPA implementation for invoice processing.

2. Design a Proof-of-Concept (PoC)

Once you've selected the automation process, the next step is to design and develop the Proof of Concept (PoC). The PoC serves as a limited-scope pilot to confirm the feasibility of automation and establish the business case. Its main objective is to validate the technical approach and ensure the RPA tool can execute the required work in the current IT environment.

At the PoC stage, your project team should focus on the following:

- Scope the pilot: Select one simple but painful process (i.e., "Update Proof of Delivery status"). Don't pick complex end-to-end processes for your PoC.

- Establish success metrics: You should have a clear idea of what a "win" means.

- Example: "Reduce manual data entry time by 80%" or "Achieve 99% accuracy in data transfer."

- Vendor selection: Select an RPA tool (e.g., UiPath, Automation Anywhere, Microsoft Power Automate) that integrates well with your specific legacy systems (e.g., SAP, Oracle, or custom mainframe WMS).

Important: A successful PoC provides concrete evidence of RPA's value. For example, the pan-European logistics company Raben Group deployed a PoC to automate the generation of spot offers, a process that previously took 15 minutes. The automated version took only 21 seconds, leading to faster sales responses. This initial success provided the justification to scale the initiative.

3. Assess Viability

With a successful PoC in place, you need to evaluate the workflow's viability. This phase is a step up from technical viability to the overall business viability of scaling the RPA deployment. It involves analyzing the potential ROI, identifying risks, and securing buy-in from key stakeholders across the business.

The viability assessment should answer several critical questions:

- Technical feasibility: Was the bot interrupted by legacy system latency? Were there any bot breaks due to changes in the carrier's website UI?

- Scalability: Is higher-volume processing easily scalable, or can it be extended to similar processes across other areas of the business?

- Financial soundness (ROI): Calculate the cost of ownership (license + maintenance fees) relative to the savings (e.g., if a bot saves 10 minutes per shipment and you have 50,000 shipments per year, the ROI is immediate).

- Risk audit: Assess risks to data security, especially if the bot accesses sensitive customer or customs-related information.

This evaluation builds a strong business case and helps ensure that the RPA effort is aligned with organisational strategy.

4. Drive Automation Across Departments

Once you have validated the RPA solution and its business value, transition your efforts to scaling the initiative. This phase is about moving from one pilot to multiple departments. To successfully manage this growth, organizations commonly establish an RPA Center of Excellence (CoE).

A CoE is a centralized team that manages, standardizes, and supports your RPA program at the enterprise level. Its core functions include:

- Governance: setting appropriate standards, policies, and best practices for bot development, testing, and deployment.

- Resource management: Ensuring the required resources for the successful execution of automation projects.

- Pipeline management: Defining and prioritizing automation candidates across each business unit.

- Change management: Sharing the value of RPA with employees and stewarding cultural change toward a human-digital workforce.

CoE enables faster time-to-market, promotes knowledge sharing, and helps maximize ROI for the RPA program.

5. Expand RPA Efficiency Through "Think and Learn" Features

Once the RPA program has matured, you can start improving software bots' capabilities by adding more advanced "think and learn" features. As we already stated, basic RPA is rules-based and works best with structured data, but its capabilities are limited in the context of unstructured data or multi-faceted decision-making.

By combining RPA with technologies such as optical character recognition (OCR) and natural language processing (NLP), you can develop more intelligent bots.

The combination brings cognitive RPA capabilities to enable bots to work with unstructured data and exceptions:

- "Think" (perception): Using intelligent document processing (IDP) and OCR.

- Logistics Use Case: Reading non-standardized commercial invoices or bills of lading from different suppliers. The bot "looks" at the PDF, identifies the "Total Weight" field even if it's in a different place on the page, and extracts it.

- "Learn" (language): Using NLP to understand email inquiries.

- Logistics Use Case: A bot reads incoming emails such as "Where is my cargo?" vs. "Here is the invoice," classifies them, and automatically routes them to the correct department.

6. Drive Automation Across the Enterprise

Now that you have the smart automation foundation in place, it's time to roll out RPA at the enterprise level. This phase is about rooting automation deeply in your business DNA so it becomes an integral part of the operational fabric. The objective is to build a real digital workforce that collaborates with human employees to lead end-to-end process improvement.

After validating the technology in one area, the goal is to break down silos and expand horizontally:

- Finance: Automate freight audit and payment (FAP) and days sales outstanding (DSO) reports.

- HR: Automate onboarding for seasonal warehouse staff or drivers (collecting licenses, background checks).

- Customer service: Use attended bots that let agents instantly check shipment status without jumping through 5 screens, reducing average handle time (AHT).

To move from 10 to 100+ bots, you need a centralized approach to avoid "bot sprawl" and maintenance chaos. Here's how to do it:

- Center of excellence (CoE): Create a council to govern the pool of shared resources and ensure adherence to coding standards and license management.

- Governance and security: Decide who can access the bots. Ensure the bots comply with trade regulations (such as the GDPR and customs regulations).

- Democratization: Drive "citizen developers" — business analysts on the warehouse management or dispatch team — to create simple automations for their day-to-day responsibilities using low-code platforms.

7. Apply AI/ML and Data Science to Expand RPA

The most evolved phase of RPA implementation is the integration of automation with artificial intelligence (AI), Machine Learning (ML), and Data Science. This integration is also known as hyperautomation.

Hyperautomation is what the next generation of enterprise automation will look like – intelligent systems that not only perform processes but also analyze, learn, and evolve continuously to improve them. By 2026, it is estimated that over 30% of enterprises will automate at least half of their network activities, and short-term supply chain planning decisions will be automated using hyperautomation.

With hyperautomation, RPA serves as the "arms and legs" (execution), while AI/ML serves as the "brains" (decision-making).

- Predictive analytics: Instead of just reporting a delay, predictive analytics in logistics can foresee it.

- Example: ML models are used to process weather conditions and port congestion to predict shipment delays. The RPA bot then automatically sends an email to the customer and updates the ETA in the TMS, all without human assistance.

- Dynamic route optimization: The AI considers traffic and fuel costs, then suggests a new route; RPA updates the driver's manifest in the database.

- Inventory forecasting: ML models forecast demand for a specific SKU, and RPA bots automatically create corresponding purchase orders for vendors.

8. Continuous Improvement via RPA Extensions and Innovation

The final stage of the RPA journey is not an endpoint but a continuous cycle of improvement and innovation. The technological landscape is constantly evolving, and organizations must remain agile to capitalize on new opportunities. This involves continuously monitoring the performance of the existing digital workforce and exploring new ways to enhance its capabilities.

Activities in this stage include:

- Maintenance: Update bots regularly when the underlying applications (such as a carrier's website) change their layouts.

- Process mining: Use log analysis software to check exactly how processes run. This unveils previously hidden bottlenecks and highlights opportunities for new automation.

- Expansion: keep adding "skills" to the digital workforce, such as adding chatbots for driver communication or applying computer vision for damage inspection in warehouses.

- Performance monitoring: Measure KPIs for each automated process, including bot utilization rates, processing times, and exception rates, to identify opportunities for improvement.

- Exploring new technologies: Keep an eye on digital twins, generative AI, and advanced analytics to discover new ways to extend value from the RPA platform.

- Fostering a culture of innovation: Motivate your employees to explore new automation ideas and reward them for discovering innovative solutions to business challenges.

Common Obstacles and Challenges in Logistics Invoice RPA

Deploying RPA for invoice processing in logistics presents its own set of challenges. We decided to highlight the three most pressing issues and their potential solutions.

Data Inconsistency and Unstructured Invoices

Invoices in logistics come from multiple carriers, suppliers, and partners. They also usually come in different formats: PDFs, scans, Excel spreadsheets, EDI files, etc. Bots handle structured data; when each vendor's invoice differs, the RPA tool may not accurately parse the fields, leading to errors. Data quality problems, such as missing or incorrect data, can also prevent straight-through processing.

Potential solution: Top-notch data-capture technologies (e.g., AI-powered OCR) and, whenever possible, invoice harmonization.

Integration with Legacy Systems

The logistics sector is notorious for relying on legacy IT systems (e.g., older ERP, freight management, or accounting systems). Legacy systems may lack modern APIs or integration hooks, making it challenging to integrate RPA bots. An automation may, for example, need to enter invoice information into a two-decade-old accounting system that only permits data entry via a green-screen interface.

Clumsy integration can result in the bot failing regularly–should the UI of the legacy system change or lag, it may stop working. Also, incompatibilities in data format or communication protocol between the RPA tool and legacy software solutions can lead to errors.

Potential solution: Overcoming this challenge may require building custom connectors or using surface-level automation (e.g., screen scraping), which is less reliable. A comprehensive review of the IT infrastructure is essential prior to RPA deployment to anticipate integration issues. In certain instances, refactoring software with AI, or advancing or modernizing individual systems or using middleware databases/APIs may be required to enable RPA. Partnering with seasoned AI developers who have proven success in legacy logistics systems enables you to architect resilient workarounds.

Complex Processes and Exception Handling

Invoice processing may seem simple, but in practice, it can involve complex workflows and exceptions (e.g., when merchandise is damaged or an invoice doesn't correspond to a purchase order, it may require investigation). RPA is ideal for static, rule-based processes. Hence, it may not perform as well when applied to more complex processes that involve high variability or decision-making. Unexpected exceptions (edge cases not initially accounted for) may cause bots to stop or produce invalid results. If the process is not uniform across the company, the bot's logic may not apply to the company as a whole.

Potential solution: To beat this challenge, analyze and simplify processes before automating. Some cases may call for the AI/ML use (for semi-structured data or decision-making), or even a new methodology for routing complex exceptions to human personnel. It is important to have clearly defined exception-handling paths. For example, if an invoice is flagged as "No Match Found," ask the bot to send it to a human or raise an alert. Early testing with a diverse set of scenarios reveals many exceptions upfront. As new scenarios arise, companies should continuously tweak their bots.

Final World

By automating the "robotic" parts of logistics jobs, your company can achieve faster throughput, more accurate operations, and supply chains that can scale efficiently. All this can ultimately lead to better service for your customers and a healthier bottom line. Meanwhile, Impressit can be your guide to implementing RPA. We focus on AI development in places where it is most called for and can bring tangible benefits to our clients. So don't hesitate to contact us if you need help!

Roman Zomko

Other articles