Smart Lockers: The Quiet Revolution in Delivery

Technology has turned both passive storage and customers into active participants in logistical workflows. As e-commerce continues its meteoric rise, driven by an insatiable appetite for instant gratification, smart lockers emerge as the unsung heroes in this quiet revolution. These secure, automated storage units offer a seamless interface for consumers and businesses alike, bridging the gap between traditional shipping methods and the evolving needs of a digital-first society.

In this post, we examine smart locker systems as a strategic operational business approach that helps eliminate last-mile delivery issues, enhance warehouse efficiency, and, most importantly, improve profitability.

Smart Lockers Market

Smart lockers are automated storage units with digital access control. Users access lockers through keys, pin codes, RFID cards, mobile apps, or QR codes. Each use is recorded, providing a real-time trace of custody for tools, devices, packages, and personal belongings. This creates a highly efficient and secure ecosystem for managing physical goods.

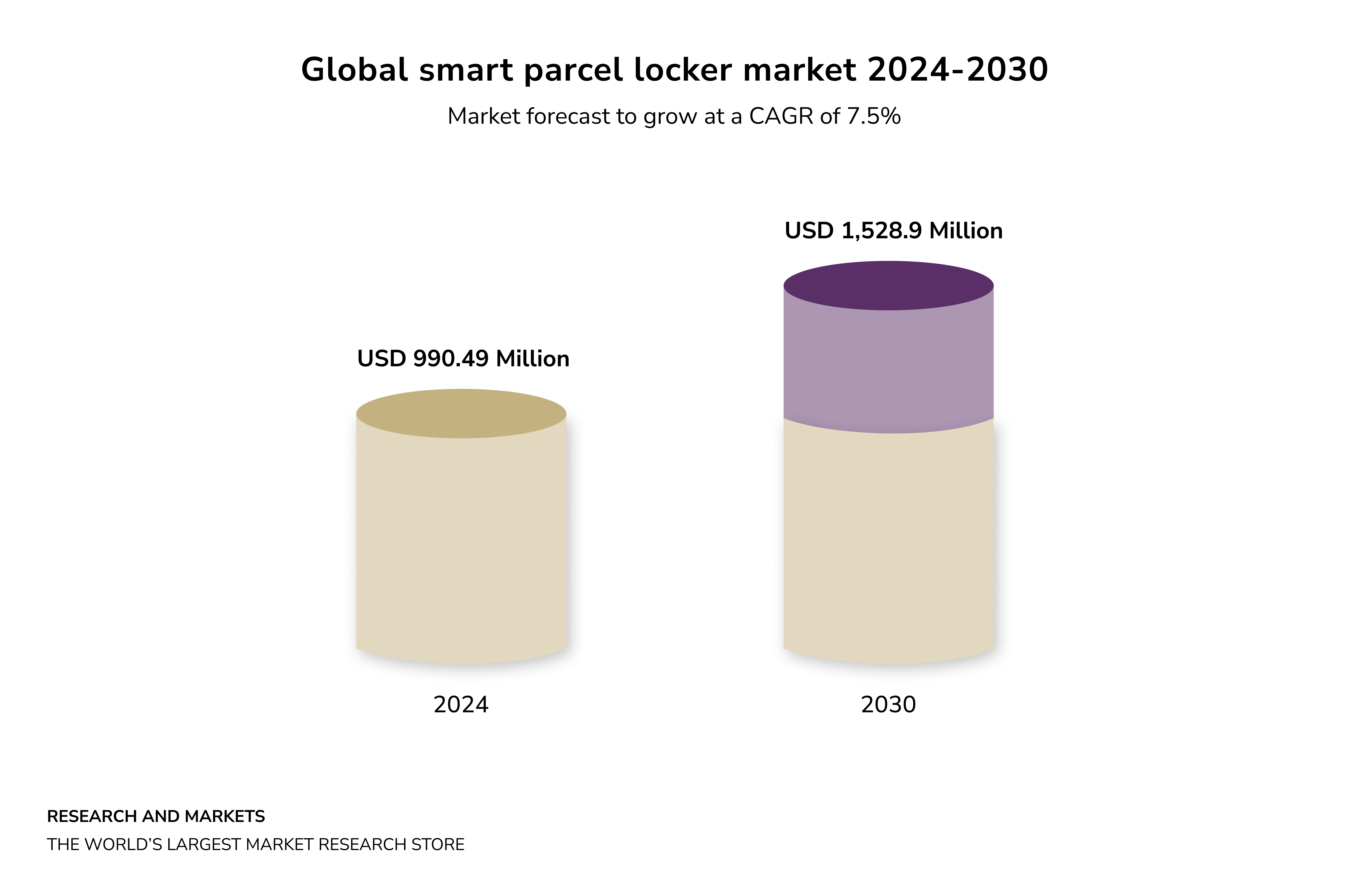

By 2030, the global smart locker market is expected to grow at a compound annual growth rate (CAGR) of 7.5%.

Many factors drive this expansion:

- E-commerce continues to grow unsustainably, resulting in delivery bottlenecks that need to be solved.

- Urbanization concentrates populations in high-density, one- and two-dimensional settings.

- The post-pandemic world has conditioned many to expect contactless interactions, resulting in the expectation of touchless locker access.

Logistics has turned previously stagnant lockers into dynamic, responsive delivery networks. Smart lockers now come with real-time tracking and biometric authentication. Intelligent automation handles everything from package sorting to predictive maintenance. These systems are deployed across various industries, including retail, healthcare, education, and corporate facilities.

How Smart Lockers Reduce Business Costs

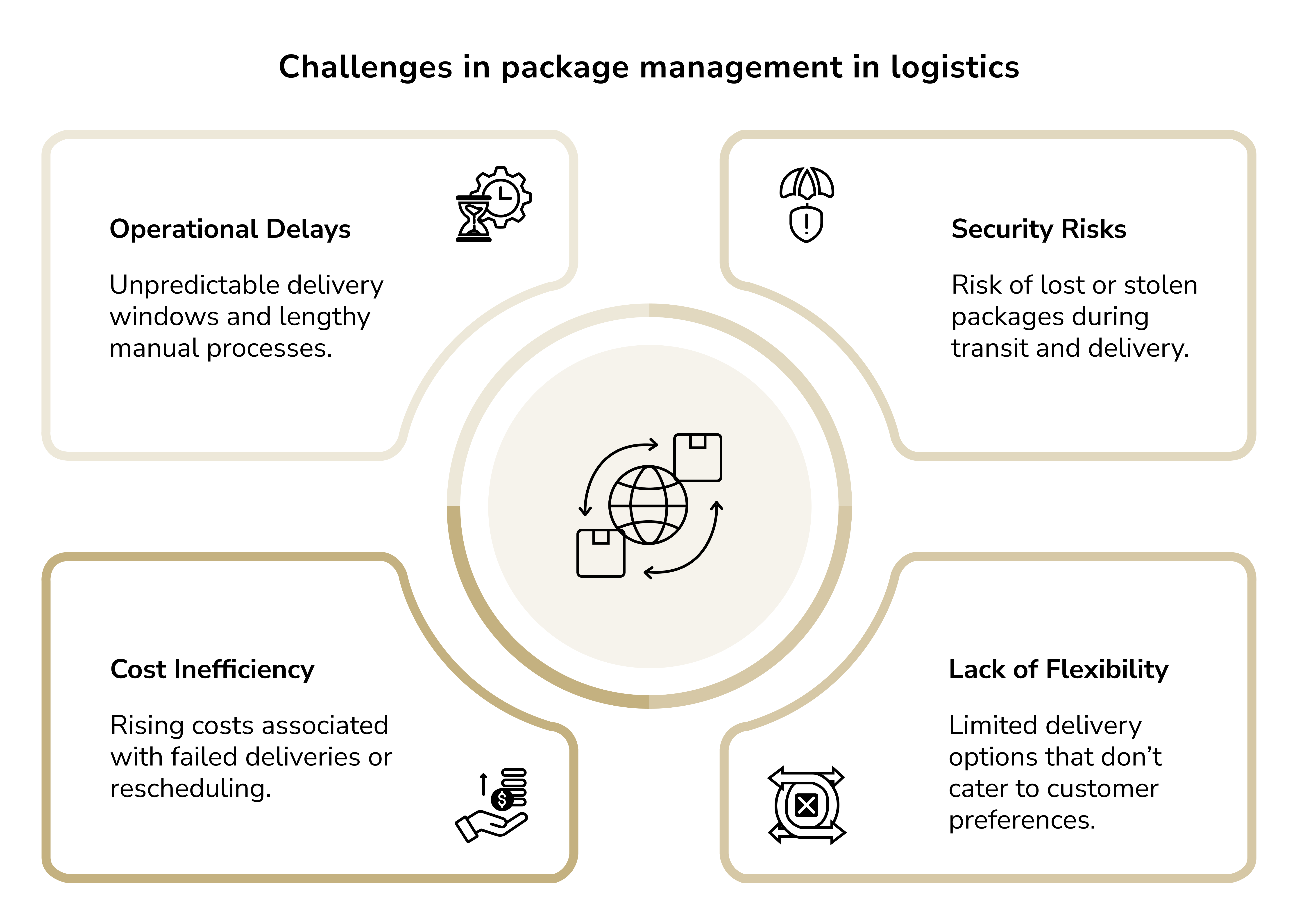

A business's profitability depends on its operational efficiency. Most of the time, resources are wasted due to misguided manual processes, human errors, and logistical delays.

The introduction of smart lockers helps mitigate logistics industry challenges.

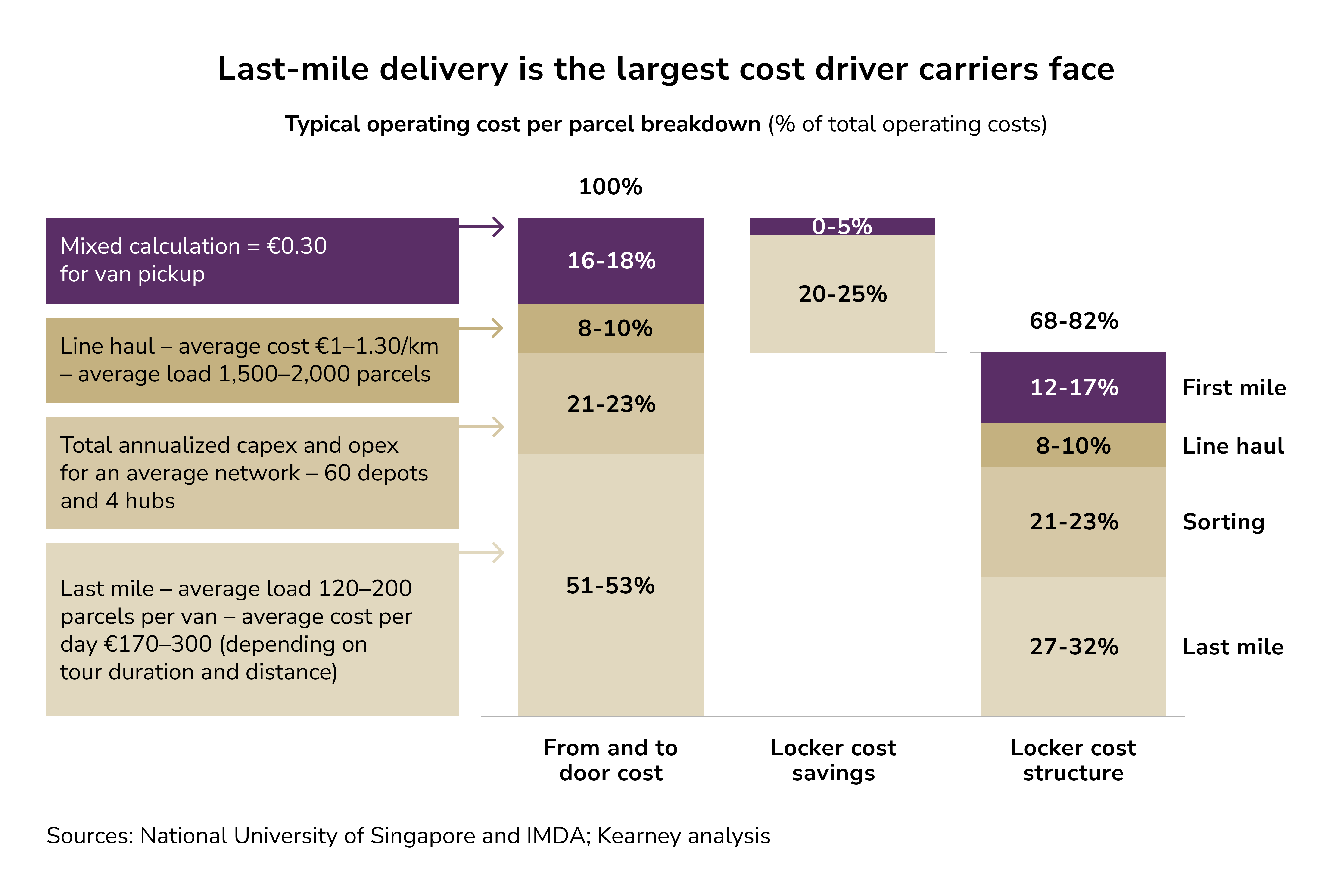

Reducing Last Mile Delivery Costs

The last mile of delivery is the most expensive part of the entire supply chain. It includes costly aspects such as failed deliveries, re-delivery attempts, fuel wastage, and wasted driver time.

Smart lockers can lower those costs as they serve as consolidated, dependable delivery points:

- Guaranteed First-Time Delivery: Couriers delivering to lockers don't have to worry about customers not being home. As a result, they have a 100% delivery success rate to lockers, and all the costs associated with re-delivery attempts and fuel wastage are significantly lower.

- Route Optimization: Drivers no longer need to make dozens of individual stops in a neighborhood as smart lockers permit consolidated deliveries. Delivering to one smart locker saves time and fuel, allows more deliveries per driver, and, overall, leads to shorter delivery routes.

- Reduced Labor Costs: With optimized routes and zero failed deliveries, more tasks can be done by the same employees. This helps address the issue of limited courier availability, enabling companies to expand their delivery operations without incurring the same rate of labor expense increases.

Minimizing Customer Service Issues

With every package that is lost or delivered late, customer satisfaction decreases, and valuable resources are lost.

Smart lockers solve this problem at its root:

- Elimination of Package Theft: Smart lockers eliminate customer claims for lost or stolen items by securing packages from porch pirates. Security features prevent package theft, providing customers with peace of mind.

- Automated Tracking and Transparency: Customers gain access to real-time updates and a trackable record of each ordered package's journey to the smart locker. Such transparency decreases the frequency of "where is my order?" questions while increasing their confidence.

- Flexible, 24/7 Pickup: Customers can collect their packages at their convenience, any time of day or night, reducing complaints about inconvenient delivery times.

Streamlining Inventory and Asset Management

Apart from parcel delivery, smart lockers also aid in internal asset management by introducing automation and accountability.

- Automated Audit Trails: A smart locker's asset checkout feature records every transaction, monitoring usage and creating timestamps for each event. As the record is checked, accountability is established, and misplaced assets are identified and tracked.

- Reduced Administrative Headaches: The traditional key-based system is an underwhelming approach to key loss management as it leads to long re-keying costs and security risks. With smart lockers, lost access cards can be fully deactivated, and new cards can be issued, resulting in a significantly lower security risk and a more economically balanced solution.

- Optimized Asset Utilization: Actionable analytics from the locker software show which devices are used most frequently and by whom. This data allows managers to make informed decisions about inventory levels, maintenance schedules, and resource allocation.

Streamlining the Modern Warehouse

Efficiency is the lifeblood of any warehouse or distribution center, in which every second saved translates into a more fluid and productive operation.

Smart lockers serve as a powerful tool for removing friction from daily tasks:

- Seamless Access to Essential Devices: In a busy warehouse, time spent searching for equipment is time wasted. Smart lockers can be configured with charging capabilities, ensuring that handheld scanners, tablets, and communication devices are always ready for use.

- Centralized Check-In/Check-Out: Staff can easily access fully charged devices at the start of their shift and return them at the end of their shift. The process is seamless, reducing retrieval times and enabling employees to focus on core tasks, such as managing inventory.

- Versatility in Application: Consider an employee who clocks in to work and has the equipment required for their shift automatically retrieved from their locker. Such automation enables employees to become more efficient from the moment they arrive at work, reducing the managerial time required for supervision.

Enhanced Security for Sensitive Items

Smart lockers ensure security on high-value assets and sensitive documents more effectively than traditional locks.

- Digital Access Control: Granting or revoking access on a digital platform can be done in real time. Access to the system can be easily removed, eliminating security risks, if an employee leaves the organization or loses their security card.

- Suspicious Activity Monitoring: The system can monitor and report unusual access patterns. Such an approach allows security personnel to investigate and mitigate escalating security risks in a facility.

- Employee Empowerment: Providing a secure personal space for employees can enhance their morale and job satisfaction. The protection of employees' personal belongings provides a sense of security and fosters a positive and productive work environment.

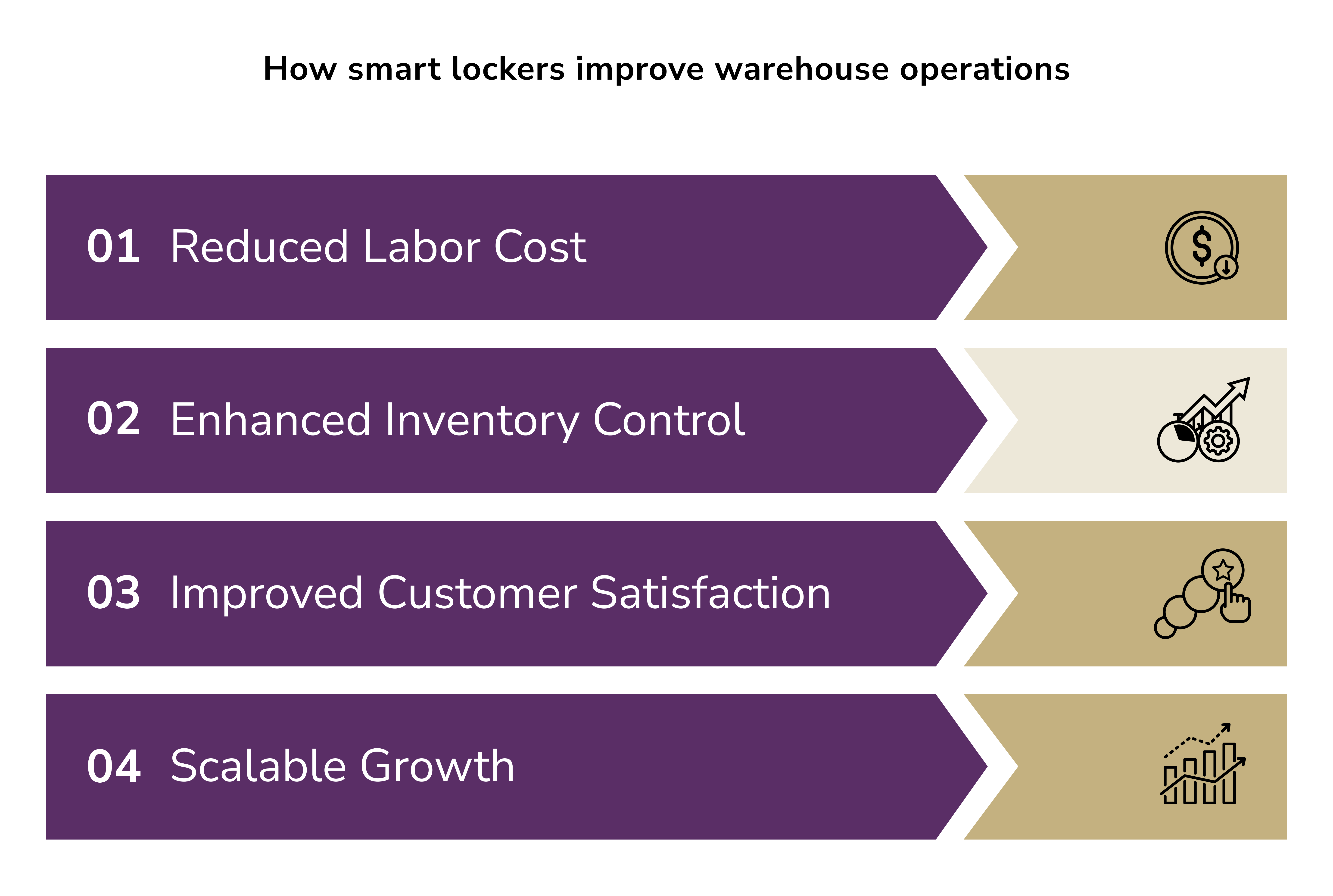

How Smart Lockers Improve Warehouse Operations

For warehouse managers facing labor shortages, rising costs, and increasingly tight delivery windows, smart lockers offer a straightforward and practical solution. They automate asset management, reduce administrative burdens, and foster accountability.

Automated Asset Tracking

The more assets to manage, the more opportunities there are to make mistakes, and the more time it will take to manage them effectively. Smart lockers take the guesswork out of management. They automatically log and track who accessed what item, when it was accessed, and for how long it was accessed. If a handheld scanner goes missing, you know exactly who the last person was to check it out. If a high-value tool is not returned, the system notifies you right away.

Visibility means the potential for loss is minimized, and critical pieces of equipment will be available at all times. It will also prevent managers from having to reconcile spreadsheets, chase missing items, and perform all the administrative work associated with the lost item.

Enhanced Security

Physical locks weaken over time, can be sabotaged, and ultimately fail. Compared to physical locks, smart lockers offer enhanced security through digital access control and real-time monitoring. Managers can respond to suspicious activity and risks immediately. If a locker is compromised, access logs provide a clear audit trail of events.

For employees, this creates peace of mind. They can store personal belongings or valuable tools without worrying about theft or unauthorized access. That psychological shift matters more than you might think—it builds trust and reduces workplace stress.

Improved Equipment Availability

Inversely, equipment bottlenecks in fast-paced warehouse environments can derail productivity. Smart lockers eliminate equipment access bottlenecks by automating check-in and check-out processes. Employees retrieve tools without waiting for a supervisor or hunting for storage rooms.

Some systems even send alerts when equipment is not returned on time, prompting users to take action before the issue becomes more significant. This keeps workflows moving and prevents costly delays.

The ability to scale and integrate additional units during peak season is crucial. Smart lockers adjust to operational demands. Need to change occupancy permissions for a new shift? The software does it in a few clicks. This flexibility minimizes long-term expenses and maintains system compatibility with changing needs.

Integration of AI with Smart Lockers

Smart locker systems can utilize AI strategically in three distinct ways that address the core operational challenges.

Effective Automation of Manual Processes

Manual processes create the potential for errors and delays. Business process automation driven by AI comes in handy for logistics companies. AI in smart lockers handles storage and retrieval processes to eliminate the aforementioned issues. AI systems track parcels, compartment assignments, and access processes with no human intervention, resulting in no labor costs and no misplaced deliveries.

Note: Touchless package retrieval, introduced during the pandemic, has become standard for secure parcel delivery. Users can package lockers without interacting with surfaces that may harbor infections. Touchless access is facilitated by facial recognition, biometric scans, and mobile authentication.

Real-Time Analytics for Smarter Operations

Real-time analytics comes in handy for various purposes in smart locker systems:

- AI interprets locker usage patterns and provides actionable insights. It tracks compartment usage, predicts maintenance windows before failures, and detects placement and scheduling inefficiencies.

- AI also tracks customer interactions with lockers, identifies peak usage times, and locates preferred locations and areas of pain. Businesses can use this analysis to determine the optimal placement of lockers, right-sizing, and service provisions aligned with actual demand.

- AI-powered flexible access control systems dynamically add and remove access permissions, automatically adjusting control levels in real-time through anomaly detection to engage/ disengage control features. The systems also detect patterns that may indicate a security threat.

Integration with Robotics

Smart lockers also utilize AI-generated data to automate a range of self-service functionalities, progressively eliminating the need for human monitors. Robotics allows direct control of lockers in automated warehouses and manufacturing systems.

The ability to provide IoT connectivity increases functionality. Smart lockers work in conjunction with delivery robots, self-driving cars, and building management systems, creating an integrated system that tracks the movement of assets over multiple access points. The combination of IoT and AI will ultimately redesign lockers to be less self-sufficient and more integral components within an intelligent, integrated system.

Open Smart Locker Networks

Delivering goods is becoming increasingly complex due to rising e-commerce traffic, urban congestion, and growing demands for environmentally sustainable delivery methods. While parcel lockers partially addressed the problem, the fragmented approach to delivery networks downed carrier-specific locker networks and siloed delivery networks across disparate delivery systems and technologies.

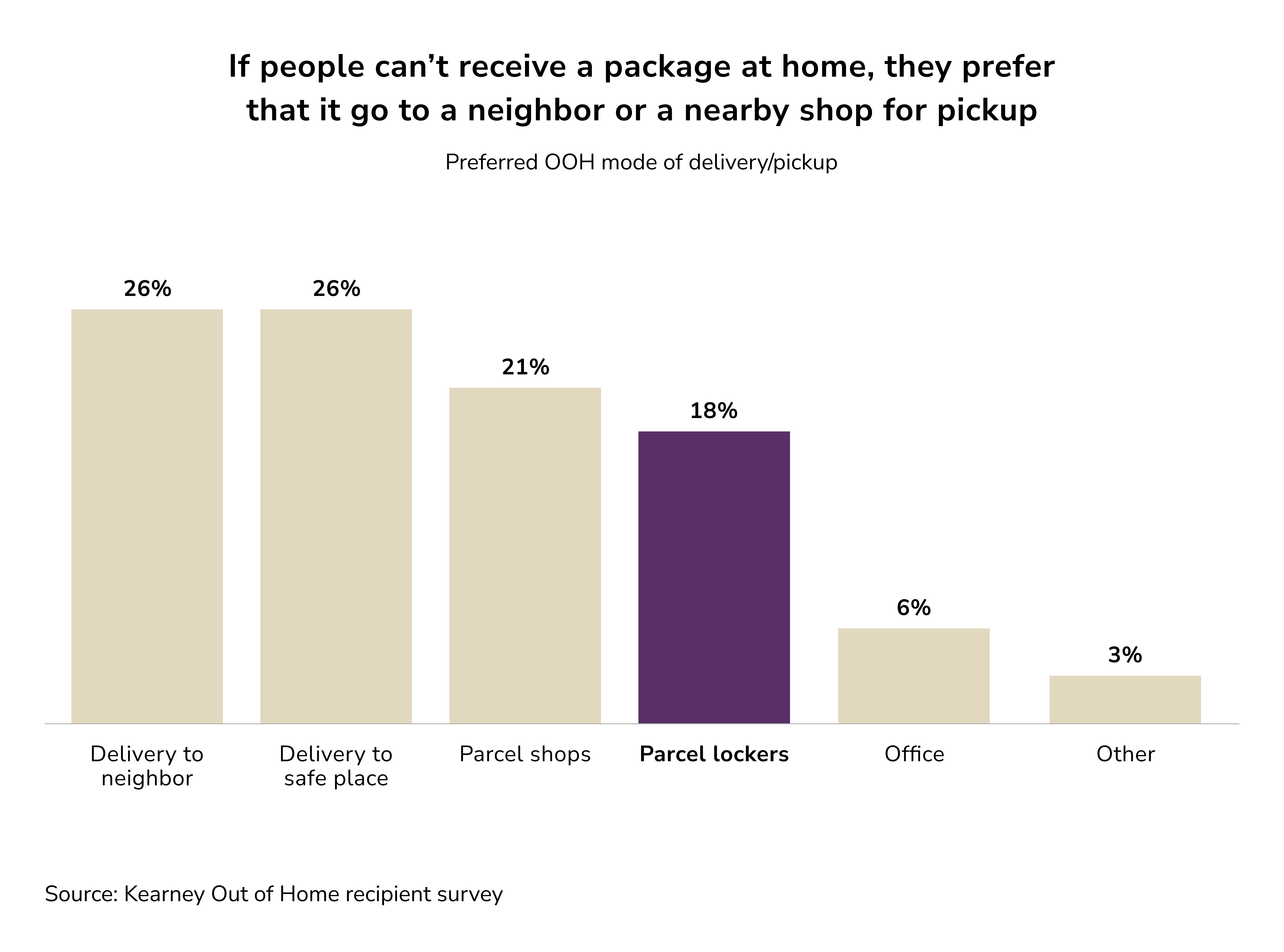

The planned out-of-home deliveries, which are expected to rise to 29% in 2025, present unique operational challenges, as 50% of consumers abandon items in their cart due to high delivery and shipping charges. Also, customers prefer that a parcel go to a neighbor when they're out of the home.

Challenges customers face in the delivery process, such as having to access different locker systems depending on the carrier, translate into a greater operational burden on carriers in the last mile of the delivery.

With open smart locker networks, shared infrastructure solves the problem, allowing multiple logistics providers to utilize the same physical spaces and consolidate deliveries for consumers at a single point of access.

DeinFach's recent launch in Germany provides a clear example of this model. Their carrier-agnostic network allows various logistics providers to seamlessly share locker systems. This works because of the technology backbone and universal protocols that facilitate access to various disparate systems, allowing them to interface with each other without the need for a middleman.

This means that interoperability is a vital driving force of innovation. Advanced systems can now maintain network reliability using self-healing technology that automatically detects and repairs locker inconsistencies across multiple carriers and hardware providers. This plug-and-play/self-service infrastructure streamlines consumer delivery and reduces back-end costs.

Eco-Friendly Smart Lockers

As more organizations pursue eco-friendliness, even the most basic elements of their facilities, such as lockers, are reconsidered. Even lockers can play a role in making environmentally friendly decisions. And for companies that wish to keep up with consumer demands, eco-friendly lockers provide organizations a simple way to reduce their environmental footprint.

Sustainable Materials

The first building block of an eco-friendly locker is its materials. Manufacturers are opting for more sustainable materials and leaving behind virgin resources. For example, instead of mining new metals, companies can reuse steel and aluminum, thereby lessening the environmental impact of new mining. This reduces the mining of metals and the energy required for manufacturing new materials, while conserving natural resources.

Note: Certain locker designs incorporate sustainably harvested materials, such as bamboo. Bamboo grows quickly, is a less intensive water user than conventional timber, and can be harvested sustainably, causing little long-term ecological damage. When lockers are constructed using recycled and sustainably harvested materials, they help establish a positive ecological balance and minimize environmental impact from the outset.

Low VOC Coatings

Lockers can also include finishing materials, which can incur environmental costs that are not always apparent. Conventional finishes emit VOCs as they dry, which then settle into the paint as a permanent feature. When a space is occupied, the VOCs become concentrated, pose serious health risks, and contribute to the space's air pollution. This is especially dangerous for schools, gyms, and offices.

To mitigate this, eco-friendly lockers are constructed with low-VOC finishes and, in most cases, zero-VOC finishes. This protects the atmosphere from pollution and ensures the safety of its occupants. This is a fine example of a small, innovative detail that can make a significant contribution to creating a non-toxic space.

Energy-Efficient Design

Many contemporary eco-friendly lockers incorporate design elements that aim to minimize electricity consumption. For example, some come with motion-sensor LED lights that only switch on when the door is opened, cutting lighting energy waste when the door is closed.

Additionally, these lockers can be designed for improved air circulation during their construction. Such a design can help sustain temperature control and, therefore, lessen the burden on HVAC systems.

Longevity

Sustainability extends beyond the materials used; it also encompasses the product's longevity. Eco-friendly lockers are built to last. They are built with high-quality, durable materials that help these lockers withstand daily use for many years. The longer they last, the less waste and fewer resources will be used to produce new units.

This longevity applies to all parts, from the heavy-duty hinges to the locking mechanisms. These lockers minimize the need for repairs and disposals, therefore providing functional sustainability and value over time.

Recyclability

An eco-friendly product considers its entire life cycle, including what happens when it is no longer needed. The materials used in lockers, like steel and aluminum, are highly recyclable. At the end of their useful life, the lockers can be disassembled, and the components can be routed to recycling facilities.

Note: This closed-loop recycling approach is a key concept in the circular economy. It saves valuable resources and minimizes waste that would otherwise end up in landfills, reducing environmental disposal impacts.

The Future of Smart Lockers: Trends to Watch Beyond 2025

As of today, smart lockers act as nodes in interconnected urban networks, sustainability ecosystems, and even autonomous supply chains. Here's what to watch as this technology matures into critical infrastructure.

Hyperpersonalization Through AI and Data Intelligence

Smart lockers are learning. AI-driven systems now analyze user behavior (pickup times, delivery frequency, and preferred locations) and adapt accordingly. Future lockers will predict when you're likely to collect a package and adjust compartment allocation based on your history.

For logistics providers, this means fewer failed deliveries and more efficient use of space. For users, it's the difference between a generic storage box and a system that knows you're always home after 7 PM. By 2030, automated lockers may be able to adjust the temperature to keep medication cool and fresh groceries from spoiling, all without the user lifting a finger.

Smart Lockers to Replace Passwords

The evolution of smart lockers renders passwords obsolete. They will rely on biometrics, including fingerprint scans, facial recognition, and vein recognition for authentication. Lockers will integrate biometrics with existing systems, such as QR codes and mobile apps, to provide users with a seamless and secure experience.

In critical sectors like pharmaceuticals, legal documents, and defense, biometrics will eliminate unauthorized access to lockers while enabling rapid access for legitimate users. In other workplaces, biometrics will enable confidential handoff systems, allowing employees to avoid manual supervision.

Smart Cities and IoT Networks

Post-2025, smart urban infrastructure will communicate and enhance the functionality of city lockers. Automated lockers will coordinate with city traffic management to optimize delivery windows and provide real-time data for city dashboards, leveraging locker usage information. The systems will also facilitate community exchanges and support municipal recycling initiatives.

These lockers will contribute to efficiency but also enhance urban life. Imagine automated lockers that serve as free library drop-offs, tool-sharing stations, and disaster supply hubs.

Circular Economy and Reverse Logistics

Smart lockers are integral to reverse logistics, encompassing returns, repairs, trade-ins, and even recycling. For customers, lockers are the primary point of contact for reverse logistics and other sustainability initiatives. It is frictionless and effortless to deposit, return, and exchange packaging for reuse, as well as rental items and old devices for refurbished ones. This makes the lockers themselves a form of infrastructure for circularity within the economy.

Deep Integration into Residential and Workplace Infrastructure

Smart lockers are now designed into buildings, no longer just bolt-on amenities. They are integrated with tenant apps, security systems, and leasing platforms. In workplaces, lockers sync with employee calendars and schedules for remote work. In multifamily housing, they consolidate and streamline services like dry cleaning and grocery delivery.

As hybrid work becomes the norm, lockers provide the personal and professional logistics link. They are essential as work and leisure activities have become interlaced, providing uninterrupted service.

App Ecosystems and API-Driven Expansion

Hardware alone does not create and sustain scams. The future is locker-as-a-service platforms with effective APIS. Food delivery apps and healthcare providers sync with contractor regulators and prescriptions. E-learning platforms now distribute course materials.

Such openness allows for lockers to be considered modular infrastructure, capable of serving a multitude of industries besides shipping. Generally speaking, the more open a platform is, the more widely it is adopted.

Robotic Integration and Autonomous Delivery

The next frontier is lockers working in conjunction with robots! Systems equipped with internal robotic arms can automatically sort packages. Drones will also be able to use lockers, as they will have aerial access hatches. Self-driving cars will be able to load and unload the lockers' compartments without human intervention.

Some systems will even be able to become mobile. Dynamic locker hubs will be able to relocate in response to demand. Think of festivals, disaster zones, and even underserved rural areas where fixed infrastructure isn't viable.

Data Monetization and Analytics-Driven Operations

Every single interaction with a locker leaves behind a piece of data. For example: how often lockers are used, the time of day, and how often a delivery is late or fails. The data left behind with each interaction is worth much more than just optimizing systems.

Analyzing anonymized data helps pinpoint areas for new locker networks, highlights which compartment sizes are underutilized, and indicates when peak demand occurs. This transforms lockers into insight engines for providers.

Impressit's Experience with Smart Lockers

We were lucky enough to work on an advanced smart locker solution developed by GoLocker. GoLocker is a network of brand-agnostic smart lockers that aims to simplify urban delivery by providing a secure, convenient, and sustainable solution for both shoppers and brands. When the company needed to enhance its B2C system and prepare for a major public-private partnership, it turned to Impressit.

When our collaboration began, we first engaged with their existing B2C system. While functional, the platform's architecture was dated and not built to support the rapid scalability GoLocker envisioned. The initial objective was clear: address immediate bugs, resolve architectural flaws, and maintain system stability.

However, a simple patch-and-repair approach is rarely the path to long-term innovation. We knew a comprehensive rewrite would be necessary to build a foundation that was logical, clear, and ready for future expansion. This dual approach—maintaining the present while strategically planning for the future—defined our initial engagement. We focused on ensuring the current system ran smoothly for its users while simultaneously blueprinting a more advanced, flexible architecture.

Integrating Security and User Insights

Handling personal delivery data, such as names, addresses, and phone numbers, carries immense responsibility. For a system like GoLocker, which partners with major carriers such as USPS, FedEx, and UPS, security is not just a feature; it is the foundation of trust.

Our team integrated robust DevOps and SecOps practices to fortify the platform. Our dedicated DevOps specialist conducted a thorough vulnerability assessment and implemented necessary measures to ensure GoLocker's system met the highest safety standards. This secured the confidence of both end-users and delivery partners.

Roman Zomko

Other articles